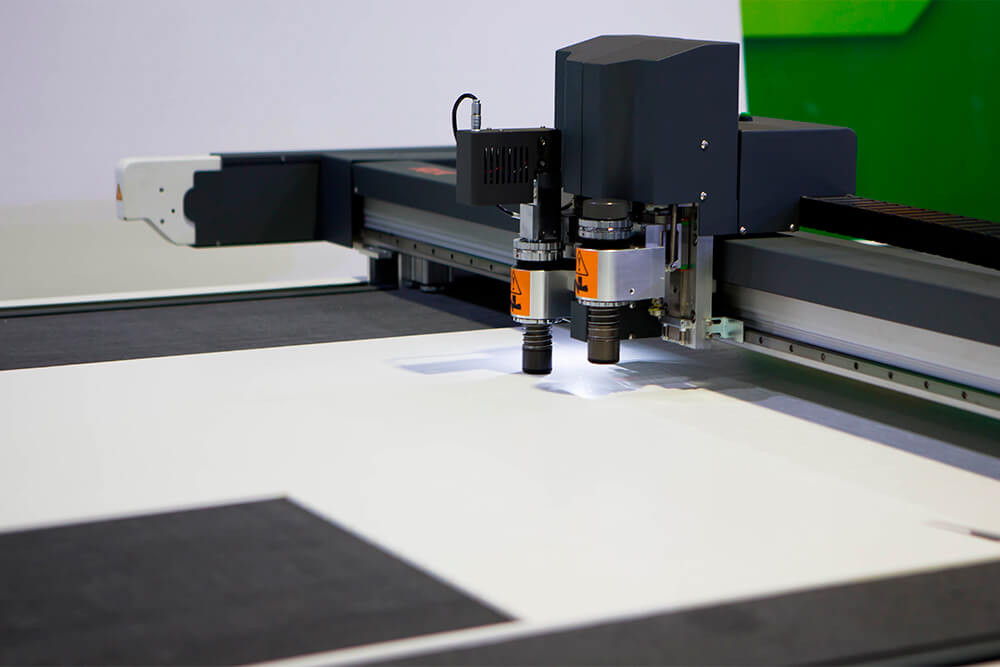

Production-grade polypropylene sheet cutting for flat parts, panels and inserts. We process polypropylene (PP) primarily by CNC routing and digital knife cutting, with CO₂ laser cutting used only on selected grades where it is technically suitable. Polypropylene is lightweight, tough and chemical-resistant, making it ideal for signage, protection panels, packaging components and industrial parts.

We cut polypropylene (PP) sheets for signage, protection, packaging and industrial applications. Flat parts only — no thermoforming in-house. Our tooling is set up for repeatable polypropylene cutting on both CNC router and digital knife tables.

We cut polypropylene (PP) sheets for signage, protection, packaging and industrial applications. Flat parts only — no thermoforming in-house. Our tooling is set up for repeatable polypropylene cutting on both CNC router and digital knife tables.

We focus on flat polypropylene cutting. If your job involves folding, forming or welding PP, we can cut the flat blanks ready for your downstream fabricator.

Polypropylene sheets are typically supplied in standard board sizes used for signage and packaging. Our CNC and digital knife beds are sized for full boards, with nesting to minimise waste and keep unit cost under control.

Our workflow is tuned for flat polypropylene cutting — protection sheets, inserts and industrial parts that arrive ready for installation, forming or fabrication by your team.

Thicker PP is routed; thin and fluted PP is digital-knife cut for clean edges and fast turnaround. We select the process that best suits each polypropylene job.

Polypropylene does not always behave well under lasers. Where PP laser cutting makes sense, we test and sign off parameters; otherwise, we route or knife-cut so you get reliable parts without melted edges.

Clear advice on polypropylene cutting for your application, realistic lead times and repeatable setups so re-orders match the first run.

Production in Botany NSW with national shipping — suited to ongoing PP panel programs, crate inserts and industrial components.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on polypropylene cutting, CNC routing, digital knife cutting and design tips for PP parts.

Whether you need polypropylene sign panels, crate inserts or industrial PP components, our CNC router and digital knife workflows are set up for repeatable, trade-ready results. Upload your files or contact us to discuss the best way to cut polypropylene for your project.

Typical applications include warehouse signage, crate dividers, industrial packaging inserts, agricultural signage, temporary site boards and chemical-resistant components. We work with logistics companies, manufacturers, agricultural suppliers and industrial contractors.

For polypropylene cutting that delivers tough, chemical-resistant parts ready for industrial use, upload your files or contact us to discuss material types and cutting methods.

Polypropylene Cutting