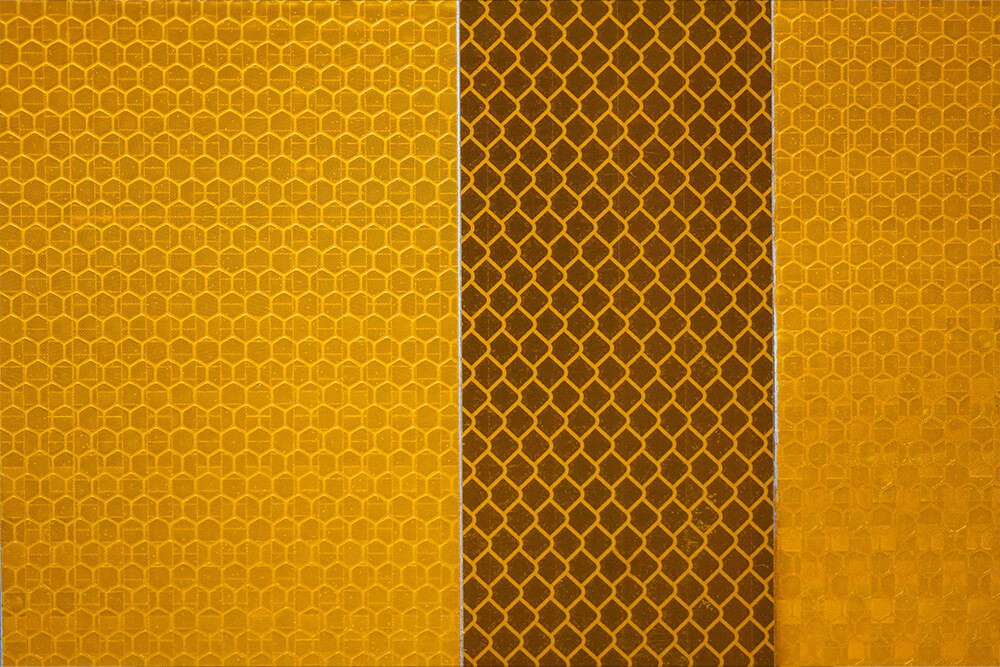

Trade-grade cutting for reflective vinyl films used in safety, traffic and wayfinding signs. We use high-precision plotter and digital knife cutting to produce clean, weedable graphics in Class 1 and Class 2 reflective films. Supplied cut, weeded (where required) and taped — ready for application.

We cut reflective vinyl (Class 1 and Class 2 films) for trade clients that need compliant, durable graphics for safety, wayfinding and branding. Flat work only — no on-site installation in-house. Clean, accurate cutting means legends, arrows and logos align with your artwork and perform as expected at night.

We typically process high-quality Class 1 and Class 2 reflective films from major manufacturers, used for road, safety and wayfinding signage. The table below summarises common use cases. Exact film choice and compliance levels depend on your project specification and standards.

| Reflective vinyl type | Typical use |

|---|---|

| Class 2 reflective vinyl | General safety, parking, site, warehouse and wayfinding signage. |

| Class 1 reflective vinyl (including prismatic) | Higher-performance traffic signage, roadwork signage and critical safety signs. |

| Engineer-grade & specialty reflective films | Street blades, branded reflective panels and specialist site applications. |

| Fleet & conspicuity reflective films | Vehicle striping, tailboard chevrons and compliance markings (subject to spec). |

*We always work to your specified brand and class of reflective film where applicable. Our cutting equipment handles reflective vinyl up to 1500 mm wide. For regulated road signage, design and compliance remain the responsibility of the project engineer or principal contractor.

We focus on cutting and supplying the reflective vinyl graphics. Substrates (aluminium, Colorbond, ACM), installation and compliance with local road and safety standards are handled by your install crews and project engineers.

Our vinyl and knife beds are set up for reflective films up to 1500 mm wide. Larger signs and graphics can be tiled into multiple panels with overlaps or joins planned to align with sign panel breaks and hardware locations.

We work daily with reflective films for traffic, safety and wayfinding signage. Artwork, tiling and packing are all planned with real installation conditions in mind — from workshops to roadside crews.

Once sign layouts and sign codes are established, we can repeat them as needed — ideal for council networks, corporate campuses, car parks and industrial sites needing consistent reflective signage.

Work from vector artwork, sign schedules or existing samples. We can align cut graphics with your sign sizes, panel layouts and mounting details, and pack by site or sign code.

Clear specs on film type, class, colour and warranty, plus realistic lead times and consistent re-runs. We are geared to support signage companies, traffic contractors and facilities teams.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on designing and using Class 1 and Class 2 reflective films in real-world projects.

Whether you need a handful of reflective signs or a full kit for a large site or network, our plotter and digital knife workflow is set up for trade-ready results and predictable lead times. Send your files or contact us to plan your next reflective vinyl cutting project.

Typical applications include traffic signs, safety signage, car park signs, construction site signage, warehouse safety markers and emergency exit signs. We work with councils, contractors, facilities managers and safety officers across infrastructure and commercial projects.

For reflective vinyl cutting that meets safety standards and delivers high visibility in all conditions, upload your artwork or contact us to discuss film selection and compliance requirements.

Reflective Vinyl Cutting (Class 1 & Class 2)