Blog · Materials

Designing parts, signage, packaging or components and not sure if your material can be laser cut? This guide walks through the most common metals, plastics, acrylics, timbers, foams, rubbers and composites we cut every week for Australian customers – and where each material makes sense.

Quick overview – what can actually be laser cut?

The short answer: a lot. Metals, acrylic, many plastics, timber, MDF, plywood, gasket materials and foams can all be laser cut when you choose the right machine (fiber vs CO2) and settings. Some materials are perfect, others are possible with caveats, and a few should never go near a laser.

Great laser materials

- Aluminium, stainless, mild steel (fiber)

- Acrylic (clear, opal, coloured)

- Birch & hardwood plywood, MDF

- PETG, PC, PP, some HDPE

- EVA & PE foam, many gasket sheets

Sometimes OK, with care

- Very thick timber and acrylic

- Certain composites and laminates

- Materials near adhesive layers

- Foams that can scorch or warp

Materials to avoid on laser

- PVC and vinyl (toxic fumes)

- Certain FR plastics with unknown fillers

- Reflective mirror surfaces on CO2 (front-coated)

For some "problem" materials, CNC router or digital knife cutting is a better choice than laser.

Metals suitable for laser cutting (fiber)

Fiber laser technology is extremely efficient for cutting flat metal sheet. It delivers high speed, tight tolerances and clean edges for fabrication and OEM work.

Typical metals we cut

- Aluminium sheet for panels, brackets and trims.

- Stainless steel for food, architectural and industrial work.

- Mild steel for general fabrication and base plates.

- Corten and weathering steels for architectural facades.

- Brass and copper for decorative and electrical parts.

Where metal laser cutting makes sense

- Engineering & fabrication – brackets, gussets, flanges and OEM parts.

- Construction & building – plates, stiffeners, balustrade components.

- Signage & display – metal letter backs, frames and mounting hardware.

Related pages: aluminium, stainless steel and mild steel laser cutting material pages.

Plastics & acrylic suitable for laser cutting (CO2)

CO2 lasers excel on many plastics because the beam is absorbed well and leaves smooth, sealed edges. Acrylic in particular looks premium straight off the machine.

Common plastics we cut

- Acrylic – clear, opal, black and colours (cast and some extruded grades).

- PETG – often used for displays and guards.

- Polycarbonate – for certain signage and industrial components.

- Polypropylene – for folders, dividers and lightweight panels.

- HDPE – for industrial and protective components, within certain thickness ranges.

- PVC foamboard / Forex (cut by CO2 or CNC depending on thickness and job).

Typical applications

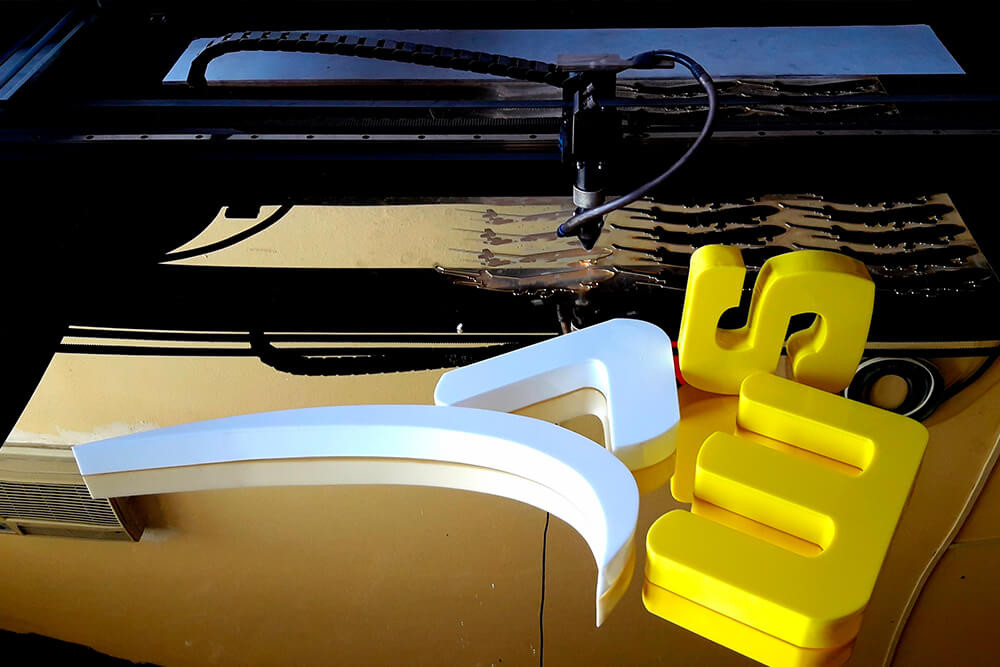

- Signage – letters, logos, lightbox faces and panels.

- Retail & point-of-sale displays.

- Protective covers and machine panels.

- Brand activations and architectural details.

Related pages: acrylic laser cutting and plastics material pages.

Timber, MDF & plywood for laser cutting

Timber and panel products cut beautifully on CO2 laser within sensible thickness ranges, and can also be routed on CNC machines for heavier structural work.

Typical sheet goods we cut

- Birch plywood for detailed work and interiors.

- Hardwood plywood for stronger decorative panels.

- MDF and HMR MDF for joinery, cabinetry and signage.

- Some veneered boards, depending on finish and adhesive.

Where timber panels are used

- Joinery & interiors – feature walls, screens and panelling.

- Shopfitting – retail fixtures and display elements.

- Signage – routered or laser-cut timber signs.

Related pages: MDF cutting, plywood cutting and CNC router cutting service page.

Foams & case inserts

Foams are typically cut using digital knife cutting for clean edges and controlled depth, with laser used in certain cases. They are ideal for protection and presentation.

Foam types we commonly cut

- EVA foam – popular for cases, props and inserts.

- PE foam – for industrial and transport protection.

- Other closed-cell foams suited to knife cutting.

Typical foam applications

- Protective case inserts for tools and equipment.

- Packaging trays and product presentation.

- Industrial protection and transport dunnage.

Related pages: foam and case inserts industry page and digital knife cutting service page.

Rubber, cork & gasket sheet

Gasket materials are cut using a mix of CO2 laser and digital knife, depending on thickness and compound. The goal is clean edges that seal reliably under compression.

Materials we typically cut

- General-purpose rubber sheet (NR, SBR, NBR, neoprene).

- Cork and cork-rubber for flange gaskets.

- PTFE and modified PTFE for chemical service.

- Compressed fibre sheet for steam and process gaskets.

Typical gasket & seal uses

- Pipe flanges and process equipment.

- Enclosure and door seals.

- Industrial plant maintenance and shutdown work.

Related page: Gaskets & Seals industry page.

Composites & special cases

Some composite materials can be laser cut, but many are better suited to CNC routing due to their structure, adhesives or fillers. When in doubt, treat composites as a question rather than an assumption.

Examples we work with

- ACM (Aluminium Composite Panel) – usually cut and V-grooved on CNC router.

- PP honeycomb and lightweight structural boards.

- Acoustic felt and certain textile composites (typically knife cut).

Materials to flag before cutting

- PVC and vinyl-based materials – not suitable for CO2 laser due to fumes.

- Unknown FR boards or filled plastics where composition is unclear.

- Mirror acrylic with front coatings – handled differently to standard acrylic.

Typical thickness & bed size limits

Exact limits depend on the machine and material, but these rules of thumb will help when you are designing parts or selecting sheet stock.

- Maximum flat sheet size across our cutting technologies: 1500mm x 3000mm.

- Metals (fiber laser): typically up to around 6mm in aluminium, stainless and mild steel.

- Acrylic (CO2 laser): commonly up to 30mm for display work.

- Timber & MDF (CO2 laser): usually up to around 12mm, with thicker material routed on CNC.

- Foams (digital knife): up to around 50mm depending on density and application.

If your design is right on the edge of these ranges, it is worth asking which process – fiber laser, CO2 laser, CNC router or digital knife – will give the best balance of quality and cost.

Laser cutting materials – FAQs

Laser Cutting Experts works with a wide range of flat sheet materials so that designers, fabricators, sign shops and industrial buyers can run entire projects through one cutting partner. Metals are cut on fiber laser, acrylic and many plastics on CO2 laser, thicker panels and composites on CNC router, and flexible materials, foams and gaskets on digital knife. Everything is based around a practical sheet size envelope up to 1500mm x 3000mm, which lines up well with standard Australian stock sizes.

When you are planning a project, the key questions are simple: what is the base material, how thick is it, what edge finish do you need and how many parts are involved? From there, the right mix of fiber laser, CO2 laser, CNC router and digital knife cutting becomes obvious. If a particular material is marginal – for example a heavily filled plastic or a composite board with unknown adhesives – we can often suggest an alternative material that will cut more cleanly and perform better in service.

Based in Sydney and servicing customers across the East Coast of Australia, Laser Cutting Experts supports everything from one-off prototypes through to ongoing production programmes. If you are not sure whether your material can be laser cut, you do not need to guess. Send through your drawings, photos or material details and we will confirm what is possible and which process will give the best balance of quality, lead time and cost.