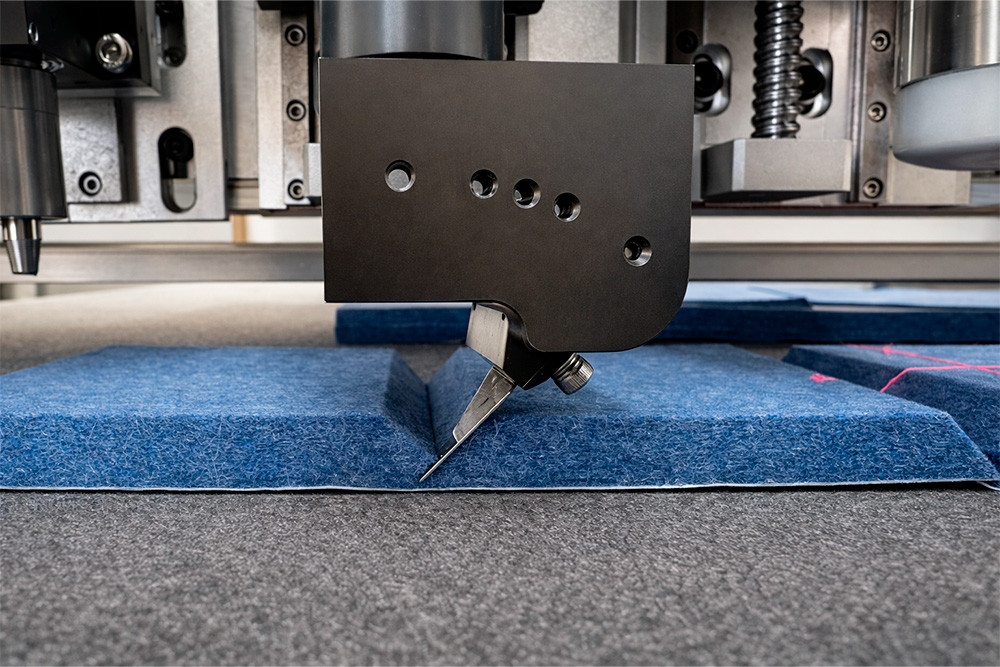

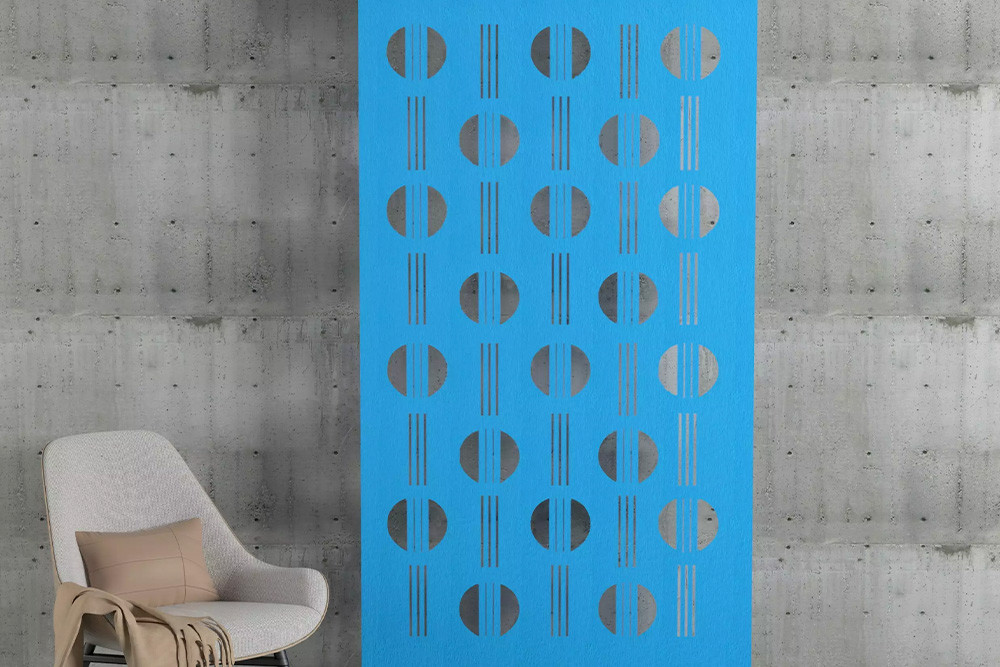

Trade-grade acoustic felt panel cutting for walls, ceilings, baffles and screens. We use high-precision digital knife tables and, where required, CNC routers to cut acoustic PET felt panels and selected composite acoustic boards into custom shapes, fins, tiles and perforated patterns. Ideal for commercial interiors, offices, education, hospitality and more.

We cut acoustic felt panels and acoustic composites for a wide range of interior projects where sound control, aesthetics and fast install matter. Flat parts only — no forming in-house. Digital knife cutting gives clean edges without fraying, ideal for visible feature panels.

Acoustic felt is typically a recycled PET material supplied as rigid or semi-rigid sheets in a range of thicknesses and densities. Some projects also use composite acoustic boards (felt on a backing). The table below reflects thicknesses we commonly cut. Exact availability depends on brand, colour and supplier, and can be confirmed when quoting.

| Acoustic felt thickness | Typical use |

|---|---|

| 6–9 mm acoustic felt | Wall panels, pinboards, small ceiling tiles and decorative cut-outs. |

| 10–12 mm acoustic felt | Desk screens, baffles, fins and panels needing more structure. |

| 18–24 mm laminated acoustic felt | Thicker rafts, feature panels and composite acoustic elements. |

| Composite acoustic boards | Felt bonded to other substrates (job-dependent, confirm method and tooling). |

*Thickness ranges above are indicative for acoustic felt panels used in interiors. We typically cut rigid and semi-rigid acoustic felt sheet on our digital knife tables. For composite acoustic panels with special backings, share product data so we can confirm the best cutting process.

Acoustic felt sheets and boards are commonly supplied in large-format sizes suitable for walls and ceilings (for example, up to 2440 × 1220 mm and beyond). Our cutting beds are sized for full panels, with efficient nesting to minimise offcuts and keep unit costs down.

We focus on flat acoustic felt panel cutting. If panels will be wrapped, framed or combined with joinery, we can cut the flat elements, mark features if required and group kits by room or area to simplify installation.

Acoustic felt panels do not love rough saw cuts. Our digital knife tables are tuned for acoustic materials, giving clean edges, tight detail and accurate perforations that look sharp in exposed ceilings and feature walls.

We work with fitout contractors, joiners, designers and acoustic brands who need panel sets delivered cut-to-size, clearly labelled and ready to install. Once panel schedules are locked in, we can repeat orders for additional stages or sites with predictable outcomes.

We can work from your CAD, PDFs or sketches, help rationalise panel sizes and joints, and structure files so cutting, labelling and packing align with your drawings and site sequencing. Ideal for larger interiors and multi-room projects.

Clear specs on sheet sizes, panel thickness, edge requirements, perforation patterns and mounting details, plus realistic lead times and consistent re-runs. Our process is built around on-time delivery and repeatable panel quality for commercial projects.

Production in Botany NSW with national shipping — suited to local office fitouts, education projects, hospitality venues and national rollouts using acoustic felt systems.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on acoustic felt panel cutting, design tips and how acoustic felt compares with other acoustic systems for commercial projects.

Whether you need a handful of acoustic wall panels for a meeting room or a full package of baffles, fins and desk screens for a multi-level office, our digital knife and CNC workflow is set up for trade-ready results and predictable lead times. Upload your files or contact us to plan your next acoustic felt project.

Typical applications include acoustic wall panels, ceiling baffles, desk screens, room dividers, feature walls and suspended acoustic elements. We work with architects, interior designers, acoustic consultants and fitout contractors across office, education and hospitality projects.

For acoustic felt panel cutting that delivers sound absorption with design flexibility, upload your files or contact us to discuss acoustic performance, fire ratings and installation requirements.

Acoustic Felt Panel Cutting in Sydney. Laser Cutting Experts Offers High-Precision Acoustic Felt Panel Cutting Services in Sydney Australia.