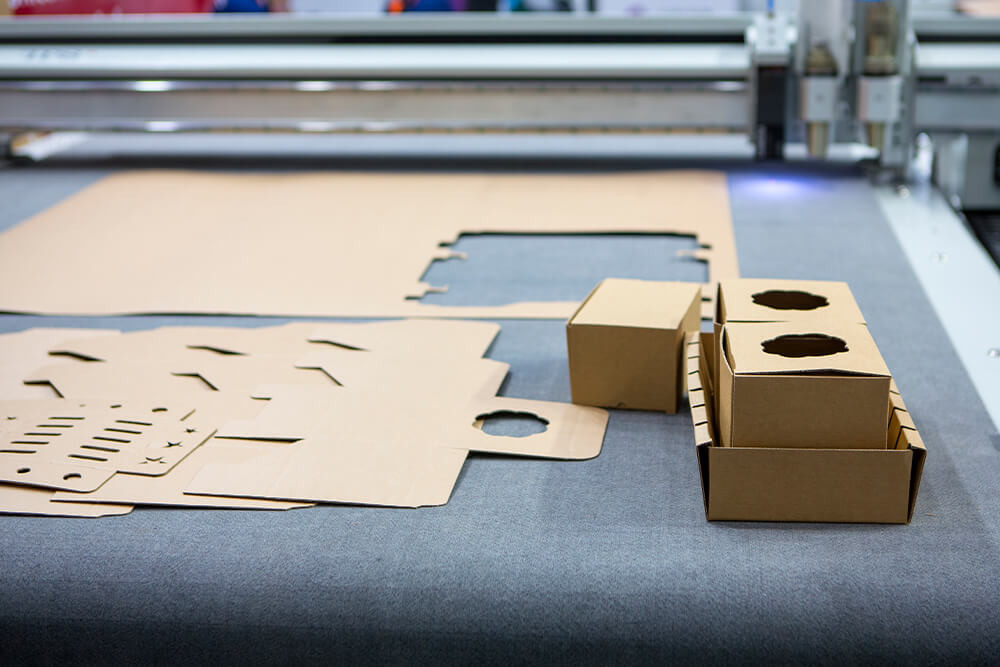

Trade-grade cartonboard cutting for packaging, sleeves, header cards and POS. We use high-precision digital knife cutting and creasing to process cartonboard (SBS and FBB) sheets into cartons, sleeves, toppers and display components. Flat parts only — supplied cut, creased and ready for gluing, folding and packing.

We cut cartonboard (SBS and FBB) for trade clients who need clean, accurate, ready-to-glue blanks and components. Flat parts only — no gluing or filling in-house. Digital knife cutting and creasing provides crisp edges and fold lines suitable for high-end printed packaging.

We typically process cartonboard in the common thickness and GSM ranges used for retail cartons and sleeves. The table below reflects the specifications we regularly see for SBS and FBB. Exact availability depends on your chosen brand and supplier, and can be confirmed when quoting.

| Cartonboard spec | Typical use |

|---|---|

| Approx. 230–270 gsm (around 0.3 mm) | Lightweight sleeves, inserts and smaller folding cartons. |

| Approx. 300–350 gsm (around 0.4–0.45 mm) | Standard retail cartons, header cards and multi-pack sleeves. |

| Approx. 400–450 gsm (around 0.5–0.6 mm) | Premium cartons, cosmetic boxes and stiffer sleeves. |

| Heavier specialty grades (above 450 gsm) | Rigid-feel cartons, presentation packs and structural POS elements. |

*GSM and thickness ranges above are indicative for cartonboard (SBS and FBB) used in printed packaging and POS. Our cutting beds accept sheets up to 1500 × 3000 mm, including large-format printed sheets. If you need specific branded grades or barrier coatings, mention this in your enquiry so we can confirm suitability.

Our digital knife beds are set up for cartonboard sheets up to 1500 × 3000 mm, covering common large-format printed sheets. Smart nesting keeps material waste low and helps reduce unit costs across both short-run and volume cartonboard jobs.

We focus on flat cartonboard cutting and creasing. You or your finishing partner can handle gluing, taping, filling and packing. We can align print and cut workflows if printing is also handled through our associated facilities.

Our knife tables are configured for cartonboard, screenboard and similar substrates. We understand the tolerances, crease behaviour and registration requirements of printed packaging and POS work.

Once your cartonboard dielines and layouts are proven, we can repeat them consistently — ideal for regular production runs, seasonal promotions and multi-SKU ranges sharing a common structure.

We can assist with refining dielines, bleed, crease and perforation layers so they are production-ready. This is especially helpful when moving from concept artwork into repeatable manufacturing files.

Clear specs on board type, GSM, coating, crease requirements and packing, plus realistic lead times and predictable re-runs. We are set up to support packaging printers, converters and brand teams.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on cartonboard cutting, design tips and how SBS / FBB grades can be used effectively in packaging, sleeves and POS projects.

Whether you need a handful of cartonboard mock-ups for a pitch or ongoing production runs for a product range, our digital knife workflow is set up for trade-ready results and predictable lead times. Upload your files or contact us to plan your next cartonboard cutting project.

Typical applications include folding cartons, product packaging, retail sleeves, cosmetic boxes, food packaging and premium gift boxes. We work with packaging designers, brand agencies, printers and product manufacturers across all sectors.

For cartonboard cutting that delivers premium packaging blanks ready for folding and assembly, upload your files or contact us to discuss board grades and production quantities.

Cartonboard Cutting SBS FBB in Sydney. Laser Cutting Experts Offers High-Precision Cartonboard Cutting SBS FBB Services in Sydney Australia.