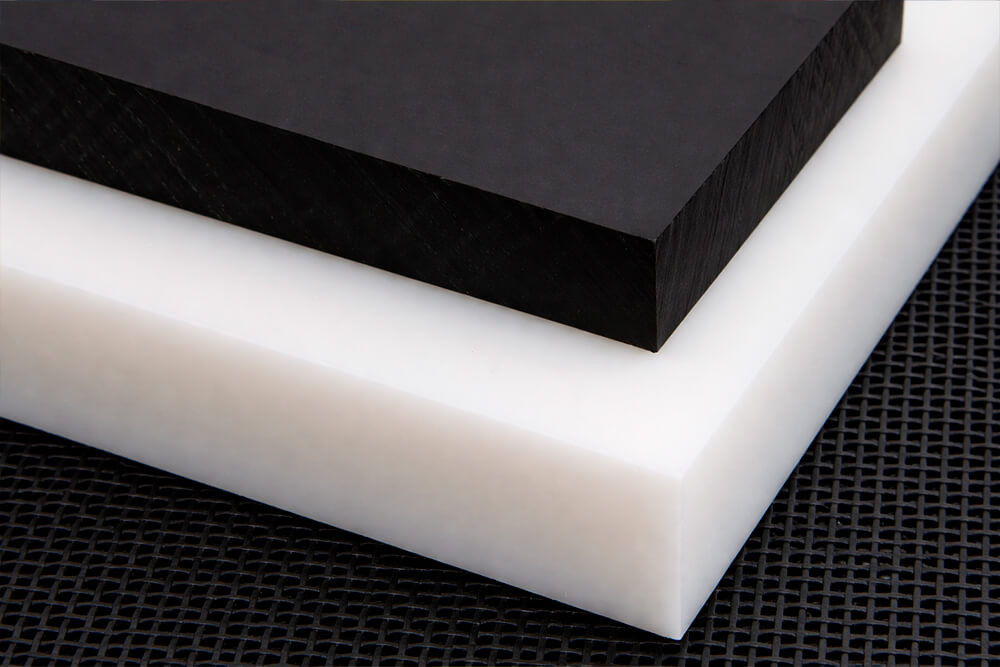

Trade-grade HDPE cutting for industrial parts, guards, liners and wear components. We use high-precision CNC router and digital knife cutting (for thinner sheet) to process HDPE (high-density polyethylene) up to around 20 mm thick, from one-offs to large production runs. HDPE is tough, impact-resistant and chemically resistant — ideal for demanding environments where standard plastics fail.

We cut HDPE sheet for a wide range of industries that need tough, impact-resistant plastics. Flat parts only — no forming in-house. CNC router cutting gives accurate, chip-free edges suitable for engineering, fabrication and industrial projects.

HDPE is a solid engineering plastic supplied in various thicknesses and grades (general-purpose, UV-stabilised, food grade and coloured sheet). The table below reflects the thicknesses we commonly cut. Exact availability depends on colour, grade and supplier, and can be confirmed when quoting.

| HDPE thickness | Typical use |

|---|---|

| 3 mm HDPE | Lightweight guards, shims, liners and small components. |

| 6 mm HDPE | General panels, covers, brackets and trays. |

| 10 mm HDPE | Higher-impact guards, wear plates and machine components. |

| 15–20 mm HDPE | Heavy-duty wear strips, bump stops and structural inserts. |

*Thickness ranges above are indicative for HDPE sheets used in signage backers, engineering, transport and industrial work. We typically cut HDPE up to around 20 mm thick on our CNC router. If you need a specific grade, colour or thicker section, mention it in your enquiry so we can confirm availability.

Completar

HDPE can be tricky to process with hand tools. Our CNC routers and digital knife tables are set up for high-density plastics, giving smooth edges, consistent radiuses and tight tolerances on repeated parts.

Once we have your HDPE profiles and nesting layouts dialled in, we can repeat orders quickly with predictable pricing and timing — ideal for OEM parts, guards and wear components that need regular replenishment.

Not sure if HDPE is the best option? We can compare HDPE vs other plastics like polypropylene, acrylic or PVC, and advise what will perform best for impact, wear, weather and food-contact requirements.

Clear specs on sheet sizes, material grade, hole positions and finish, plus realistic lead times and consistent re-runs for repeat orders. We're set up for trade, fabricators and OEMs who need HDPE parts delivered reliably.

Production in Botany NSW with national shipping — suited to local projects, multi-site rollouts and ongoing HDPE component programs for industrial and commercial clients.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

HDPE Cutting in Sydney. Laser Cutting Experts Offers High-Precision HDPE Cutting Services in Sydney Australia.