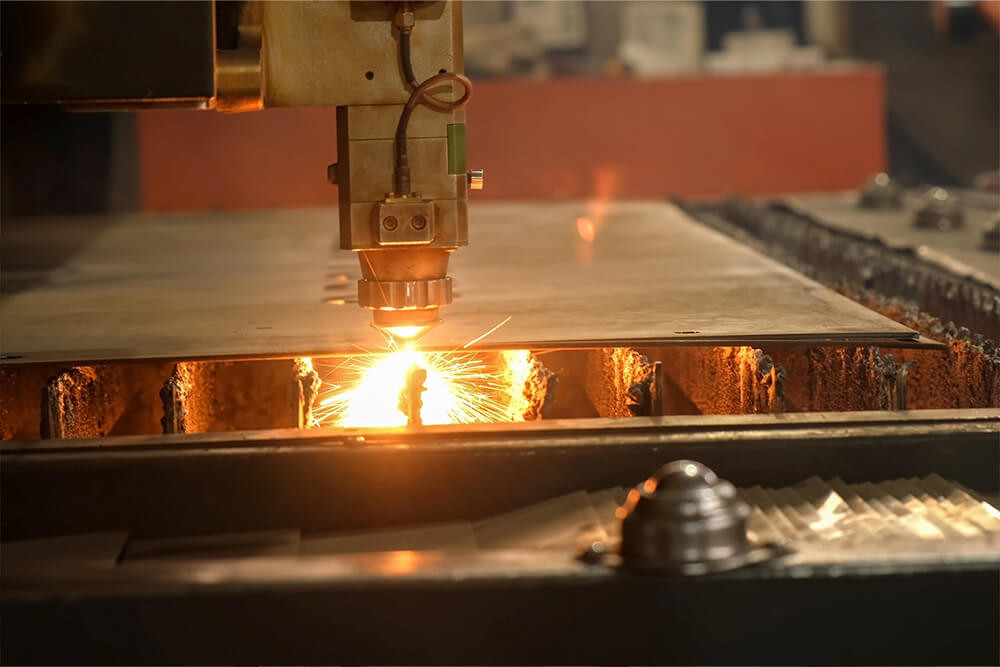

Production-grade copper sheet cutting for flat parts, plates and signage components. We cut copper on our fibre laser and CNC equipment as flat profiles only — no bending or forming in-house. Sheets up to 3000 × 1500 mm are processed for signage, electrical, decorative and industrial work, ready for your own fabrication and finishing.

We cut copper sheets for signage, electrical and decorative work where the look and conductivity of copper matter. Flat parts only — no bending or forming in-house. We supply accurately cut copper pieces ready for your own fabrication, patination and installation.

We cut copper sheets for signage, electrical and decorative work where the look and conductivity of copper matter. Flat parts only — no bending or forming in-house. We supply accurately cut copper pieces ready for your own fabrication, patination and installation.

We specialise in flat copper cutting. Any forming, soldering, patination, coating or assembly is handled by your own fabricators, electricians or metalworkers.

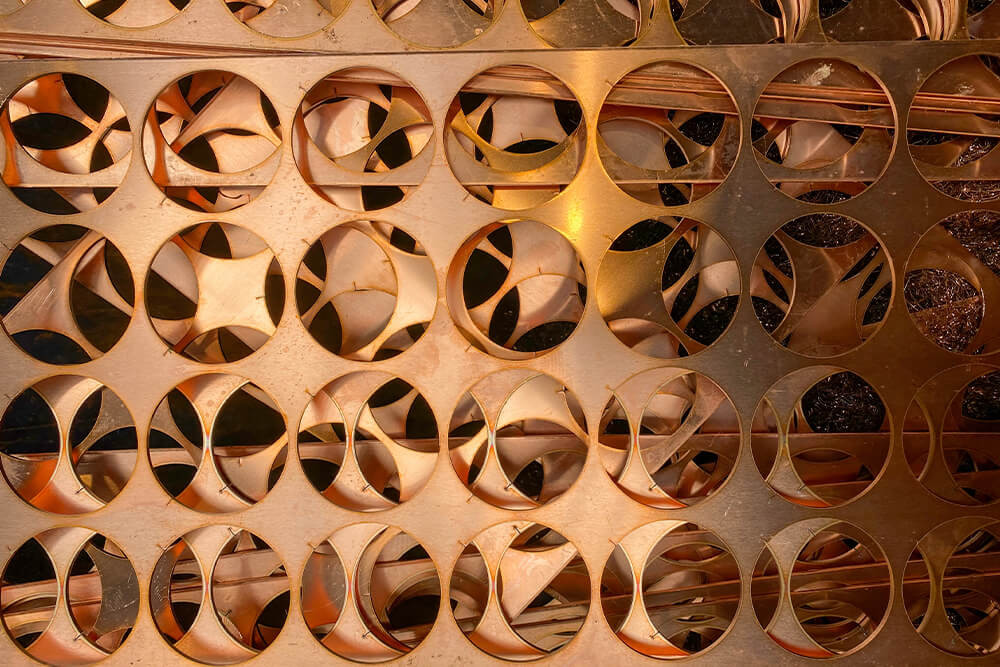

We regularly cut copper letters, plates and panels for signage and interiors, so our nesting, handling and cutting parameters are tuned to real-world decorative work rather than one-off experiments.

Our fibre laser is set up for non-ferrous sheet cutting, including copper, within the practical sheet and thickness ranges used for flat signage and light fabrication parts.

We're explicit that we cut flat copper parts only. Forming, brazing, soldering and installation are handled by your own metal shop or electrical team, which keeps scope and responsibility clear.

Production in Botany NSW with national shipping — suited to local signage and fitout projects through to national brands that need copper details produced centrally.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on copper cutting, design considerations and best practice for fibre-laser cut copper parts.

Whether you need a single copper feature piece or a full run of copper letters and plates, our fibre laser and CNC workflows are set up for trade-quality results and predictable lead times on copper sheets up to 3000 × 1500 mm. Upload your files or contact us to plan your next copper cutting job.

Typical applications include copper letters and logos, architectural features, decorative panels, restaurant and bar signage, nameplates and heritage restoration projects. We work with signmakers, architects, designers and heritage specialists across premium commercial and residential projects.

For copper cutting that delivers premium finish and distinctive aesthetics, upload your files or contact us to discuss copper grades, finishing options and installation requirements.

Copper Cutting in Sydney. Laser Cutting Experts Offers High-Precision Copper Cutting Services in Sydney Australia.