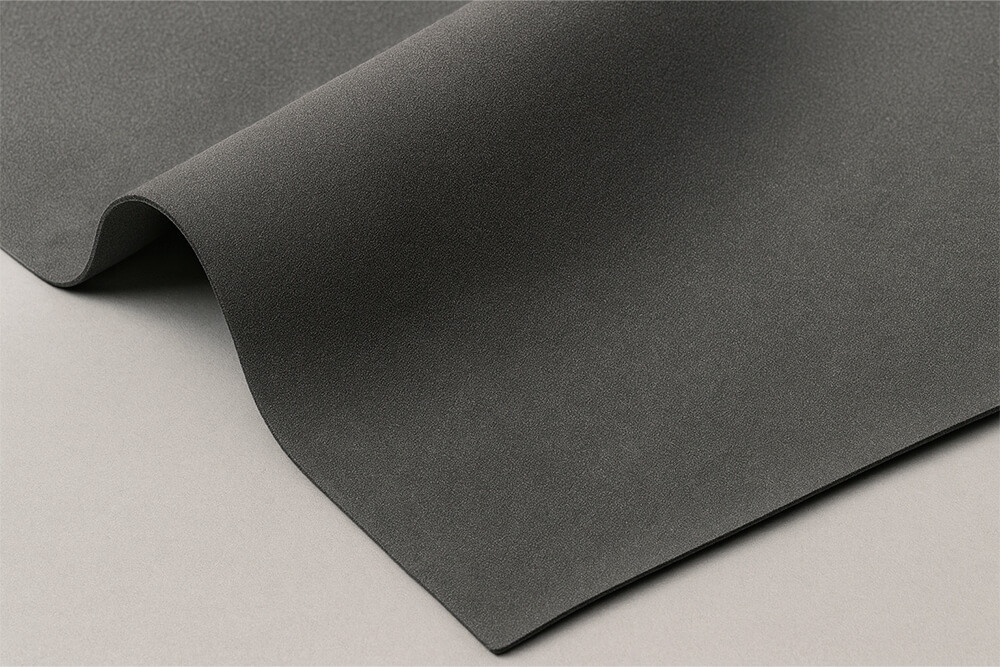

We cut Neoprene (CR) rubber from flat sheets for gaskets, seals, pads, strips and isolation components. Digital knife and CO₂ laser cutting for Neoprene sheets up to 3000mm x 1500mm – tuned for clean edges, accurate profiles and repeatable nesting.

Neoprene (chloroprene rubber, CR) is a versatile gasket and sealing material with good weathering, oil and water resistance. We mostly cut Neoprene for:

Neoprene is a closed-cell or solid rubber (depending on grade) with good flexibility and durability. It behaves differently to rigid plastics or metals: it can stretch, compress and rebound under the blade, and edges need to be managed to avoid excessive taper or melting. We select cutting methods and parameters around your Neoprene thickness, hardness and application.

For many Neoprene gaskets we favour knife cutting to maintain edge quality and minimise heat-affected zones, using laser selectively where detail or throughput requires it.

We can work from CAD, DXF, gasket drawings or physical samples where original files are not available.

Our goal is to deliver Neoprene parts that can go straight into assembly, maintenance or installation without re-work.

Neoprene behaves differently to sheet metal or rigid plastics. Our cutting workflow – tooling, feeds and hold-down – is built around keeping edges sharp, holes accurate and parts flat enough to seal as intended.

We understand that gaskets and seals live between mating surfaces. Hole sizes, clearances and edge quality are all considered so parts seal correctly, not just look right on the table.

Neoprene is often combined with metal flanges, plastic housings and fasteners. Because we also cut those materials, we can help align patterns and tolerances across the full assembly.

We regularly act as a behind-the-scenes cutting partner for metal fabricators, OEMs and maintenance teams. Consistent parts, clear communication and repeatable supply are the focus.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Neoprene (CR) Cutting in Sydney. Laser Cutting Experts Offers High-Precision Neoprene (CR) Cutting Services in Sydney Australia.