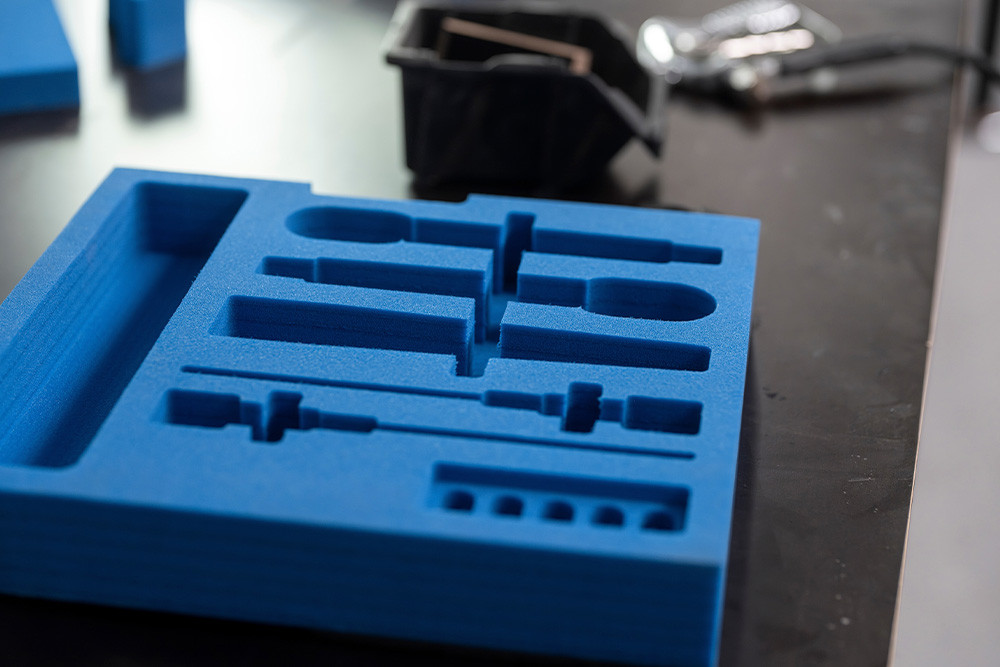

Custom-cut foam inserts and case liners for tools, equipment, samples and fragile products. We cut clean, repeatable profiles for protective packing, tool control and presentation kits — made in Sydney and shipped Australia-wide. Upload your DXF for instant pricing, or send a parts list and measurements if you need help creating cut-ready fill

We support manufacturers, service teams, AV and camera crews, trade contractors, and brands with inserts that protect gear, speed up setup, and keep kits consistent across teams and sites.

We cut a wide range of foams and soft materials for inserts. Share your application (impact protection, tool control, presentation, chemical exposure) and we'll recommend a suitable option.

Best for: tool kits, service cases, presentation packs and general protection.

Best for: delicate products, protective packing and lid liners.

If you're unsure what foam you have, send a photo and thickness and we'll help identify a workable cutting method.

We can cut foam sheets and boards up to 1500 mm × 3000 mm. Larger inserts can be split into sections for easier transport and assembly inside the case.

We cut inserts and liners — we do not supply the cases. If you already have a case model, send internal dimensions and we'll fit the insert to suit.

Foam inserts often need a real-world test for clearance and usability. We can prototype quickly, then lock the layout for repeat orders — perfect for tool kits, service teams, and product shipments.

Instead of relying on complex 3D machining, we build depth using stacked foam layers. It’s cost-effective, easy to replace, and works well for many equipment and tool layouts.

The goal is simple: everything has a place. Clear cut-outs and consistent layouts make it easier to spot missing tools, pack quickly and keep kits standard across multiple teams.

We work with OEMs, maintenance teams, resellers and packaging partners. Supply your own foam or use ours — either way we’ll deliver parts labelled and packaged so your team can assemble kits without confusion.

Based in Botany, we ship across Australia. For local clients, you can bring a case and equipment for a quick fit check before rolling into production.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

A well-designed foam insert protects equipment, speeds up packing, and reduces missing items. Laser Cutting Experts produces custom foam inserts in Sydney using digital knife cutting and CNC cutting so you can go from concept to repeat production without tooling delays.

If you already have an existing insert you like, we can replicate it and improve usability (finger pulls, clearer spacing, better nesting) where appropriate. For new kits, we can help you plan a layout that balances protection, speed of use and material efficiency.

Custom foam inserts for cases, kits, products and presentations. Prototype first, then repeat production with consistent results. Cut in Sydney with fast shipping Australia-wide. Send your DXF or brief and we’ll help you get a foam insert that looks professional and works reliably in the field.

Laser Cutting for Foam & Case Inserts in Sydney. Laser Cutting Experts Offers High-Precision Laser Cutting Services for Foam & Case Inserts in Sydney Australia.