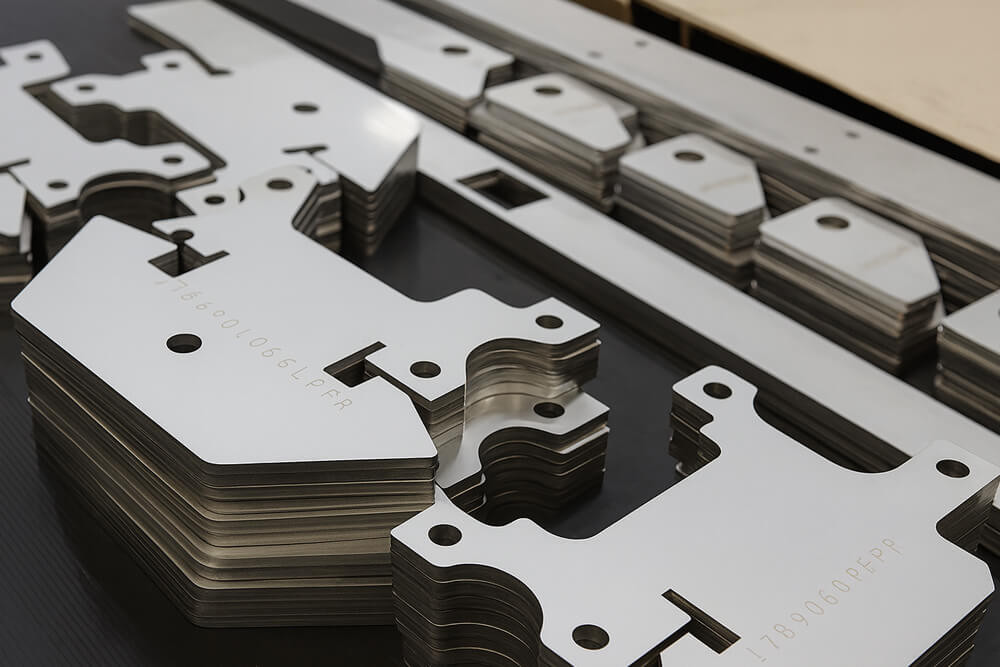

Flat laser cut plates, brackets and utility components for builders, contractors and infrastructure projects. Mild steel, galvanised, stainless, aluminium and construction boards — cut to size, ready to install on site. Upload DXF for instant pricing from our Sydney-based laser cutting team.<p></p>

We support commercial builders, infrastructure contractors, fit-out teams and utilities providers with flat components that make installation faster and more consistent. Ideal for structural connections, façade details, services support and repeat site details.

Typical in-house materials we cut for construction and infrastructure components.

For very thick plate or specialised coatings, talk to us about feasibility before ordering.

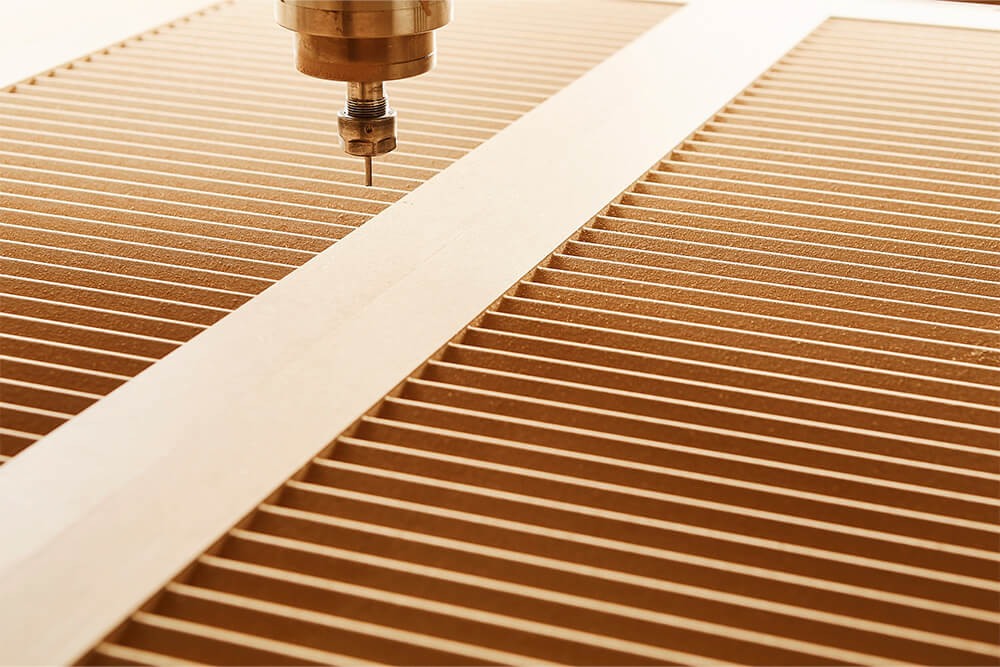

Boards and sheet are typically processed up to 1500 × 3000 mm on laser, router or knife depending on material.

Values shown are our normal production window for consistent edge quality and reasonable lead times.

We cut metals, plastics and boards up to 1500 × 3000 mm. Larger elements can be tiled, spliced or jointed on site as required.

We specialise in flat components — plates, brackets, trims and templates. You take care of on-site installation and fabrication; we make sure the parts arrive cut accurately and on time.

We understand programme dates, crane bookings and shutdown windows. Parts are quoted with realistic lead times and packed so your installers can identify and use them quickly.

Once a detail is dialled in, we keep the DXFs and nests on file. That means consistent hole centres, bracket dimensions and plate sizes across multiple stages or sites.

We can supply common steel plate, stainless and boards, or cut components from your own material where suitable. Either way, you deal with a single cutting partner who understands construction details.

Based in Botany, we ship across Sydney, Melbourne and Brisbane. You can call, email or visit to discuss tricky details before you commit to a full run.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Laser Cutting Experts is set up as a trade partner for construction and infrastructure teams, not a retail metal shop. Our focus is flat laser cut parts and CNC-routed components that drop into your own installation workflow with minimal drama.

Our laser cutting service in Sydney is built for long-term relationships with construction, fit-out and infrastructure clients. We keep communication tight, explain what is and is not realistic, and remember your preferences on corner relief, tabbing, marking and labelling. The aim is simple: parts that arrive when you expect them and fit the way you drew them.

Typical jobs range from small bracket packs and plate kits through to full sets of components for structures, façades and plant decks. We also help with maintenance and remedial work where a worn or non-compliant detail needs to be replaced quickly from a sketch or sample.

If you have upcoming work in commercial construction, infrastructure or utilities, send through your DXFs or a brief. We can advise on material choice, plate thickness and small drawing tweaks that will help your job run smoother through both our machines and your site team.

Laser Cutting for Construction Components in Sydney. Laser Cutting Experts Offers High-Precision Laser Cutting Services for Construction Components in Sydney Australia.