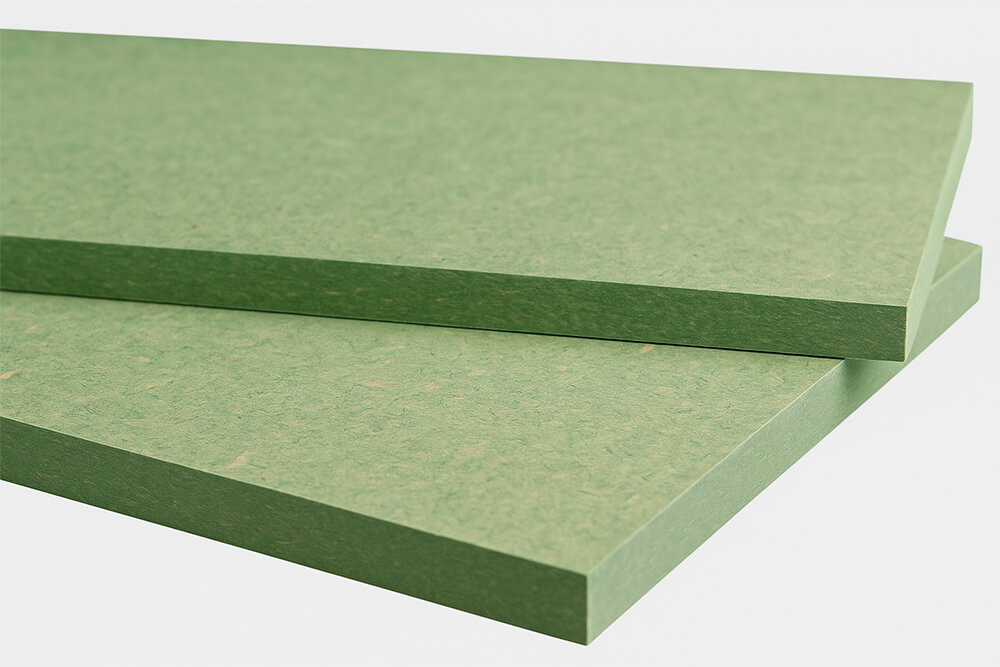

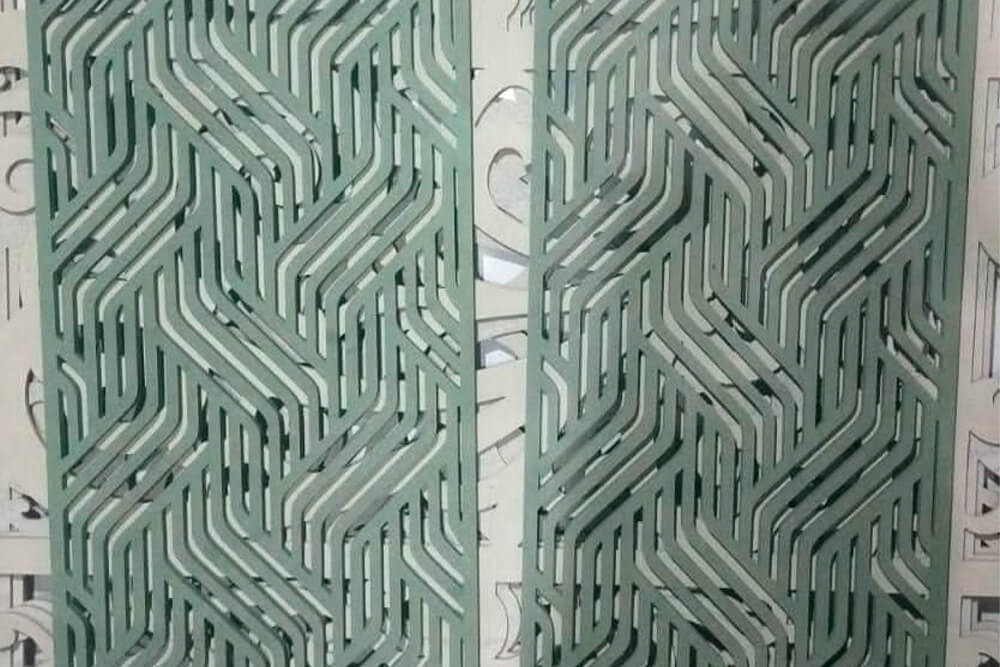

Trade-grade HMR MDF cutting for joinery, cabinetry and commercial interiors where moisture resistance matters. We use high-precision CNC router cutting to process moisture resistant MDF sheets into cabinet parts, wall panels and detailed components. Flat parts only — supplied routed, drilled and ready for edging, laminating, painting or assembly.

We cut HMR MDF panels for a wide range of joinery and interiors projects where durability and moisture resistance are important. Flat components only — no forming or wrapping in-house. CNC router cutting provides clean edges and accurate details suitable for edging, laminating and finishing.

We commonly process moisture resistant MDF sheets in the thickness ranges used for cabinet carcasses, shelving and wall panels. The table below summarises typical thicknesses and where they are used. Exact availability depends on your supplier and spec, and can be confirmed when quoting.

| HMR MDF thickness (approx.) | Typical use |

|---|---|

| 12 mm HMR MDF | Back panels, wall linings, cabinet backs and light duty panels. |

| 16 mm HMR MDF | Standard cabinet carcasses, shelves and general joinery components. |

| 18 mm HMR MDF | Heavier duty carcasses, open shelving and larger span panels. |

| 25 mm HMR MDF and above | Benchtop substrates, thick shelving and high-load cabinetry elements. |

*Thickness ranges above are indicative for moisture resistant MDF panels. Our cutting beds accept boards up to 1500 × 3000 mm. If you need specific branded boards, fire-retardant variants or other specialised products, mention this when you enquire so we can confirm suitability.

We focus on flat moisture resistant MDF panel cutting. Edgebanding, laminating, painting and full joinery assembly are typically handled by your own shop or fitout partners. We can match cutting details to your hardware and finish systems.

Our CNC router beds are set up for HMR MDF sheets up to 1500 × 3000 mm, covering the main panel sizes used by joiners and shopfitters. Efficient nesting reduces waste and keeps unit costs down for both one-off projects and ongoing production runs.

We understand how HMR MDF is used in kitchens, bathrooms, laundries and high-use commercial joinery. Panel sizes, fixings and hardware locations are planned to work with your shop drawings and install sequences.

Once cabinet libraries, panel sets and hardware positions are dialled in, we can repeat work quickly with predictable pricing and timing — ideal for builders, shopfitters and volume joinery programs.

Work from cabinet exports, DXF/DWG or fully nested sheets. We can assist with nesting, grain direction on any faced boards and part labelling so assembly is efficient and errors are minimised on site.

Clear specs on thickness, board grade, edge exposure and hardware, plus realistic lead times and consistent re-runs. We are geared to support busy joinery shops, builders and fitout contractors.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on designing with moisture resistant MDF and how to get the best out of CNC cut HMR panels.

Whether you need a handful of moisture resistant MDF panels for a small project or full cabinet packages for a large fitout, our CNC router workflow is set up for trade-ready results and predictable lead times. Upload your files or contact us to plan your next HMR MDF cutting project.

Typical applications include bathroom cabinets, laundry joinery, kitchen carcasses, hospitality fitouts, commercial washroom vanities and wet area shelving. We work with joiners, cabinetmakers, shopfitters and builders across residential and commercial projects.

For HMR MDF cutting that handles moisture exposure while maintaining dimensional stability, upload your drawings or contact us to discuss material specifications and project requirements.

HMR MDF Cutting in Sydney. Laser Cutting Experts Offers High-Precision HMR MDF Cutting Services in Sydney Australia.