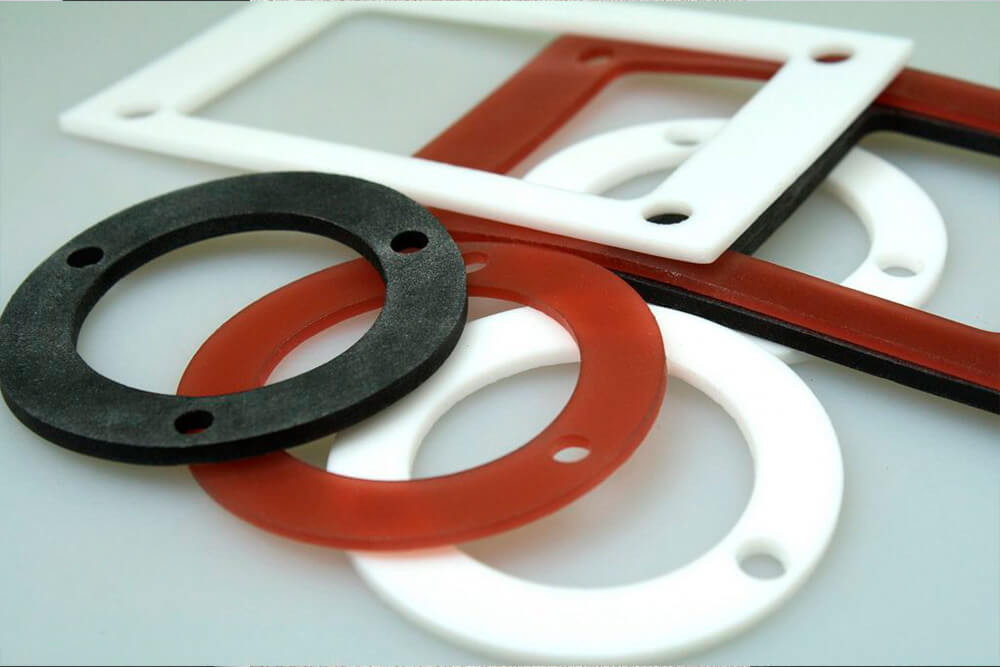

We cut flat gaskets, seals and shim components from sheet materials for OEMs, maintenance teams and fabricators. Rubber, foams, cork, PTFE, fibre and thin metals — precision cut on digital knife, laser and CNC router from sheets up to 1500mm x 3000mm, ready to bolt up and go.

Laser Cutting Experts is a cutting partner for gasket manufacturers, maintenance departments and fabrication shops. We do not compound materials or handle moulded products — our focus is flat gasket and seal profiles cut from sheet and roll goods, supplied as finished parts or kits that line up with your hardware and flange standards.

We work with most flat gasket and sealing materials supplied in sheet or roll form, provided they are compatible with digital knife cutting, laser cutting or CNC routing. For specialised compounds, you can supply the stock from your preferred manufacturer and we will handle the cutting.

*Metal gaskets and shims are limited to flat profiles within our standard thickness and bed size envelope.

From simple ring gaskets to complex multi-hole profiles, we cut flat seals to match your bolt patterns, hardware and mating faces. You provide the dimensions or a clean sample; we return repeatable parts.

We can work directly from your CAD files, conversions from existing drawings or reverse engineered scans and samples where originals are not available.

Careful handling and packing is critical with thin gasket materials. We plan kitting and packaging to match how your team will install or assemble the parts.

Our workflow is built around flat panels and sheet goods. That makes us efficient at cutting gaskets and seals from standard sheet sizes, even when you need a mix of materials and thicknesses in one job.

Shutdowns and breakdowns do not wait. We can prioritise urgent gasket and seal jobs where timing is critical, while also supporting longer-term programmes with stable pricing and repeatable part libraries.

Once a gasket set is proven on site, we can treat it as a kit with a single reference. Future orders simply call up that kit ID, simplifying purchasing and inventory.

Use your existing gasket material suppliers and send us sheets or rolls for cutting, or talk to us about standard rubber, foam and plastic grades for more general service applications.

A few practical guidelines help ensure gaskets seal correctly, are easy to install and can be reproduced reliably when you need more.

A simple process that covers everything from one-off emergency gaskets to ongoing OEM supply.

Share drawings, CAD files, samples or scanned outlines, plus material preferences and service conditions.

We price based on material type, thickness, sheet usage (up to 1500mm x 3000mm), cutting time and kitting requirements, highlighting any optimisation opportunities.

Files are checked, adjusted if required and nested to maximise yield and keep gasket sets grouped logically.

Parts are cut on the most suitable machine, inspected against critical dimensions and kitted or bagged according to your requirements.

Gaskets are dispatched to your site or warehouse. Proven designs are catalogued so future orders are simply a matter of quoting the part or kit ID.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Laser Cutting for Gaskets & Seals in Sydney. Laser Cutting Experts Offers High-Precision Laser Cutting Services for Gaskets & Seals in Sydney Australia.