Production-grade EPDM rubber and gasket cutting for flat seals, pads and industrial parts. We cut EPDM sheets and rubber gasket materials on our digital knife tables and CNC flatbeds up to 3000 × 1500 mm, supplying flat components only — no moulding or vulcanising in-house. Perfect for seals, gaskets, isolation pads and custom rubber parts.

We cut EPDM rubber sheets and other gasket-grade rubbers for a wide range of industrial and commercial applications. Flat parts only — no moulding, bonding or assembly in-house. You handle final fit-up, we provide accurately cut EPDM and rubber components.

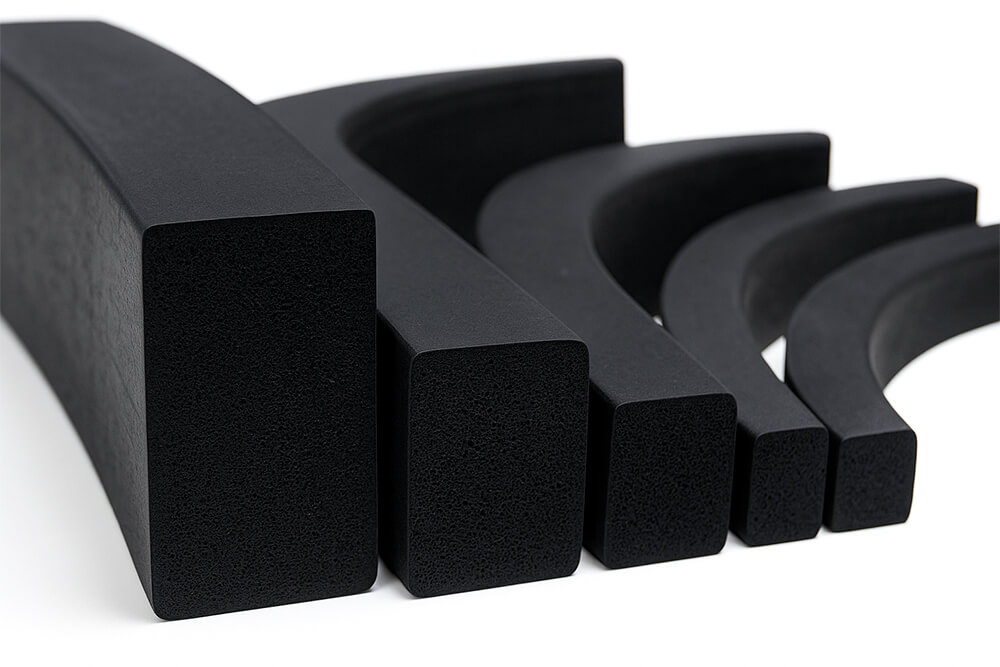

We cut a broad range of EPDM and rubber gasket sheet materials in various thicknesses. The table below is indicative only; exact suitability depends on the specific compound, hardness and job requirements.

| Material type | Indicative thickness range | Typical use |

|---|---|---|

| EPDM rubber sheet | Commonly thin to mid-gauges | Weather-resistant seals, gaskets and isolation pads. |

| General rubber gasket sheet | Varies by compound | Flange gaskets, washers, cut shapes and pads. |

| Foam / sponge rubber (selected types) | Thin to medium | Sealing strips, cushioning and light isolation pieces. |

*Thickness ranges above are deliberately indicative. If you are working with a specific EPDM grade, rubber compound, hardness (Shore A) or thickness, include that in your enquiry so we can confirm suitability for digital knife or CNC cutting and the best setup on our 3000 × 1500 mm flatbeds.

We focus on flat rubber gasket cutting. Any bonding, adhesive backing, assembly or installation is handled by your own fabrication or maintenance teams.

We cut EPDM and rubber gaskets using digital knife and CNC methods rather than lasers, avoiding burnt edges and fumes while keeping holes and profiles accurate for reliable sealing.

Our workflow suits industrial, mechanical and fabrication environments — from one-off replacement gaskets to regular batches of pads and seals for OEMs and contractors.

Many projects combine rubber gaskets with metal plates, plastic panels and other components. We can cut most of those flat parts in one place, simplifying procurement and logistics.

Production in Botany NSW with national freight — suited to local maintenance teams through to national programs that need reliable EPDM gasket cutting on demand.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on EPDM rubber cutting, gasket cutting and design tips for knife-cut rubber parts.

Whether you need one-off replacement gaskets or a full production run of EPDM seals and pads, our digital knife and CNC workflows are set up for trade-quality results and predictable lead times on sheets up to 3000 × 1500 mm. Upload your files or contact us to plan your next EPDM rubber and gasket cutting job.

Typical applications include flange gaskets, door seals, weatherstripping, isolation pads, HVAC gaskets and industrial sealing applications. We work with maintenance teams, fabricators, OEMs and engineering contractors across all industries.

For EPDM rubber and gasket cutting that meets your sealing requirements and arrives ready to install, upload your drawings or contact us to discuss material specifications and project timelines.

EPDM Rubber & Gasket Cutting in Sydney. Laser Cutting Experts Offers High-Precision EPDM Rubber & Gasket Cutting Services in Sydney Australia.