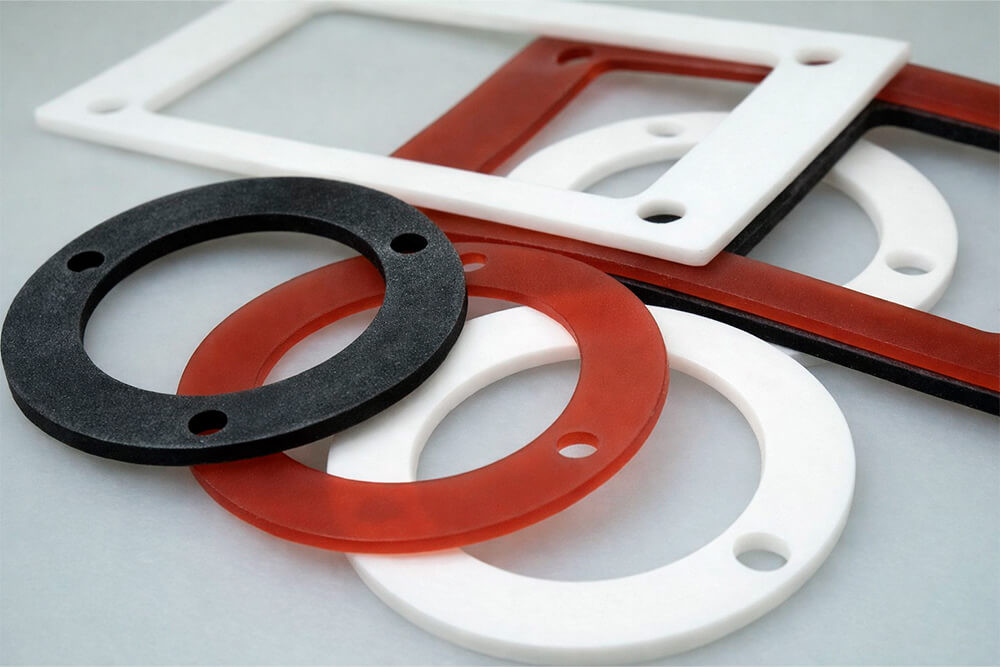

Trade-grade cutting for silicone rubber sheets used in high-temperature, food-grade and general sealing applications. We use high-precision digital knife and CNC cutting to turn flat silicone sheets into gaskets, pads, strips and custom profiles. Flat parts only — supplied cut, kitted and ready to bolt up or bond into place.

We cut silicone rubber sheet for trade clients that need temperature-resistant, flexible and often food-contact-friendly gaskets and pads. Flat parts only — no moulded or extruded components in-house. Clean knife cutting provides accurate shapes and holes suited to hygienic and high-performance applications.

We typically process silicone rubber sheets in the thickness and hardness ranges used for high-temperature, food-grade and general sealing applications. The table below reflects the ranges we commonly cut. Exact availability depends on your sheet spec and supplier, and can be confirmed when quoting.

| Silicone spec (approx.) | Typical use |

|---|---|

| 1–2 mm silicone, 40–60 Shore A | Light-duty gaskets, membranes and cover seals. |

| 3–5 mm silicone, 50–70 Shore A | General-purpose food-grade and high-temp gaskets, seals and pads. |

| 6–10 mm silicone, various hardnesses | Heavier-duty pads, isolation elements and impact-absorbing seals. |

| Sponge / foam silicone sheets | Compression seals, door seals and environmental gaskets (subject to spec). |

*Thickness and hardness ranges above are indicative for silicone rubber gasket and sealing sheet. Our cutting beds accept sheets up to 1500 × 3000 mm. If you need specific branded grades, FDA/food-grade, platinum-cured, high-temperature or other specialised silicone compounds, mention this in your enquiry so we can confirm suitability.

We focus on flat silicone sheet cutting. Moulded seals, tubes, o-rings and complex extrusions are outside the scope of this service, but flat gaskets and pads often work alongside those products in the same system.

Our digital knife and CNC beds are set up for silicone sheets up to 1500 × 3000 mm, covering typical sheet formats used in industrial and food-grade supply. Efficient nesting reduces scrap and keeps unit costs competitive for both small and large orders.

We understand the demands around temperature, cleaning and hygiene where silicone rubber is used. Our cutting approach respects those constraints and supports traceable, repeatable gasket production.

From one-off replacement gaskets to ongoing OEM kits, we set up projects so repeat orders are simple: call off by part number, kit ID or equipment reference.

Work from CAD, DXF, existing drawings or samples. We can check bolt circles, flange sizes and clearances, then nest parts efficiently against your silicone sheet size and grade.

Clear specs on silicone grade, colour, thickness, hardness and media, plus realistic lead times and consistent re-runs. We are geared to support plant engineers, OEMs, gasket suppliers and maintenance contractors.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on flat silicone gasket cutting, design tips and how silicone sheet can be used effectively in sealing and isolation projects.

Whether you need a handful of silicone gaskets for a critical piece of equipment or full kits for an OEM product range, our digital knife and CNC workflow is set up for trade-ready results and predictable lead times. Upload your files or contact us to plan your next silicone rubber cutting project.

Typical applications include food grade gaskets, pharmaceutical seals, high temperature gaskets, oven door seals, autoclave gaskets and medical device components. We work with food processors, pharmaceutical manufacturers, OEMs and maintenance teams across hygiene-critical industries.

For silicone rubber cutting that meets your temperature, hygiene and flexibility requirements, upload your gasket drawings or contact us to discuss material specifications and compliance needs.

Silicone Rubber Cutting in Sydney. Laser Cutting Experts Offers High-Precision Silicone Rubber Cutting Services in Sydney Australia.