We cut flat parts for mining and heavy industrial projects – from wear plates, guards and brackets through to signage, panels and shims. Mild steel, stainless, aluminium, plastics and rubber cut by laser, CNC router and digital knife from boards up to 1500mm x 3000mm, ready to bolt up on site.

Laser Cutting Experts is a flat-part cutting partner for mining sites, heavy industry, OEMs and fabrication shops. We do not fabricate complete skids or structures – we specialise in cutting the flat components that feed into your own fabrication or maintenance workflows, with realistic lead times and consistent quality.

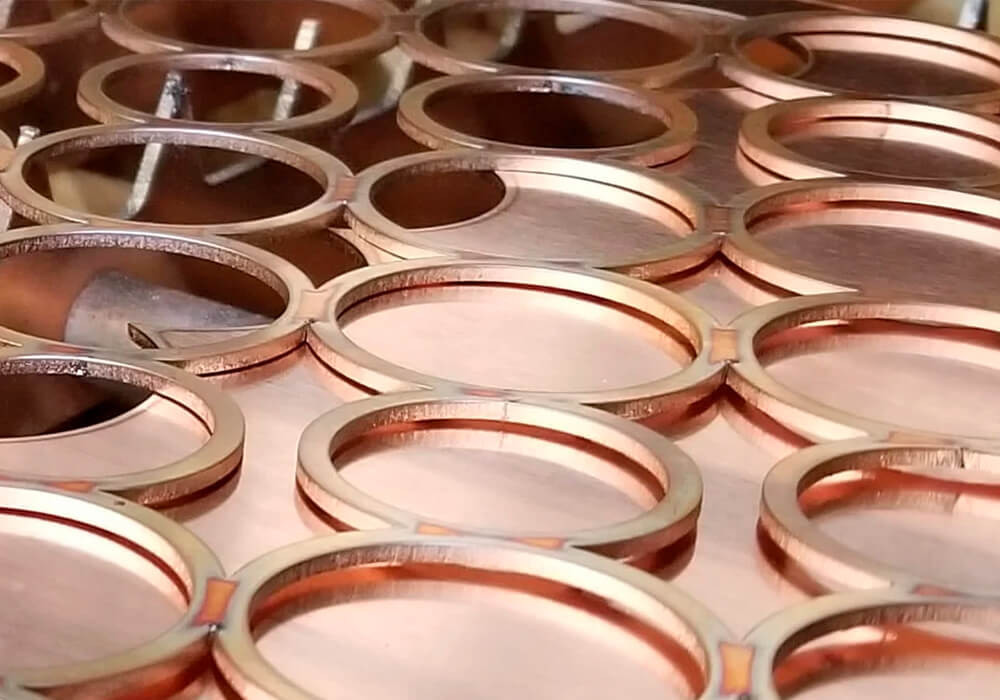

We work with the common metals and sheet materials used around plants, processing facilities and heavy industrial sites, within our flat cutting envelope and standard thickness ranges.

The list below covers the kind of flat parts we regularly cut for heavy industry. You keep control of the design and engineering; we focus on reliable cutting and logical kitting.

Exact thickness ranges depend on material type and job requirements. Critical tolerances and fit-up details can be discussed at quoting stage so we choose the right cutting approach.

We focus on cutting and part preparation. Where required, we can coordinate with your own coating, galvanizing or painting suppliers to align part handling and packing.

Shutdowns, outages and tie-ins rarely move slowly. We plan cutting around realistic timeframes, communicate clearly if something changes, and help prioritise what needs to land on site first.

Parts can be bundled and labelled by work pack, area or piece of equipment so crews are not sorting through mixed pallets in the dark. This can be the difference between a smooth shutdown and a long night.

We handle one-off urgent parts as well as standard kits and repeat components for OEMs and fabricators. Once a design is proven, re-ordering is simply a matter of quoting the drawing or kit reference.

Modern plants use steel, aluminium, plastics, rubber and composites side by side. We cut all of these flat on the same set of machines, simplifying purchasing and coordination for planners and supervisors.

Small decisions in the design phase can save hours on site. These guidelines help keep cutting efficient and installation straightforward.

A straightforward process that works whether you are planning a shutdown, building new equipment or stocking spares.

Share the scope, timing, drawings and any existing part references. We confirm what is suited to laser, router or knife cutting.

We price based on material, sheet usage (up to 1500mm x 3000mm), cutting time and any kitting requirements, flagging potential optimisations.

Files are checked and nested for yield and practicality on site. We agree on labelling and packing conventions, especially for shutdown work.

Parts are cut on the most suitable machines, checked against key dimensions and grouped into work packs, pallets or crates ready to ship.

We coordinate deliveries to site or your workshop. Proven parts and kits are catalogued for quick re-ordering in future campaigns or outages.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Laser Cutting for Mining & Industrial in Sydney. Laser Cutting Experts Offers High-Precision Laser Cutting Services for Mining & Industrial in Sydney Australia.