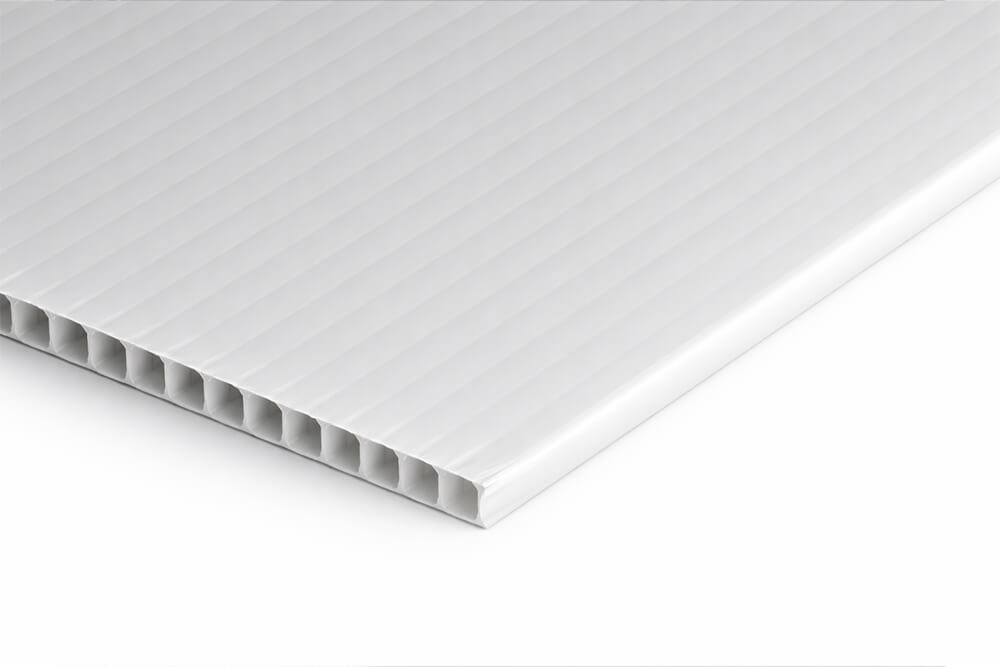

Trade-grade corflute sheet cutting and UV direct printing for signage, protection panels and displays. We use the latest digital knife cutting technology to cut corflute up to 10 mm thick, from one-offs to large production runs. Corflute (fluted polypropylene) is lightweight, rigid and economical — ideal for temporary and semi-permanent applications.

We cut and print corflute (fluted polypropylene) for a wide range of industries that need lightweight, cost-effective panels. Flat parts only — no forming in-house. Digital knife cutting gives clean edges with no crushing or ragged fibres.

Corflute is a fluted polypropylene sheet available in several standard thicknesses. The table below reflects the thicknesses we commonly cut and print. Exact availability depends on colour, grade and supplier, and can be confirmed when quoting.

| Corflute thickness | Typical use |

|---|---|

| 3 mm corflute | Short-term indoor signs, small hanging panels, box inserts. |

| 5 mm corflute | Most real estate, construction and event signage; general site signs. |

| 8 mm corflute | Larger panels and signs needing extra rigidity, heavier-duty site boards. |

| 10 mm corflute | Heavy-duty protection sheets, large panels and panels exposed to wind. |

*Thickness ranges above are indicative for corflute sheets used in signage, protection and packaging work. We cut corflute up to 10 mm thick on our digital knife tables. If you need a specific grade, colour or fluting direction, mention it in your enquiry so we can confirm availability.

We focus on flat corflute cutting and printing. If you plan to fold, crease or fabricate corflute into boxes or complex shapes, we can cut and crease panels where required — just include this in your brief.

Corflute sheets are typically supplied in signage-friendly sizes (for example, up to 2440 × 1220 mm and beyond). Our digital knife beds are sized for full corflute boards, with nesting to minimise waste and keep unit costs down.

We don't rough-cut corflute on saws. Our digital knife tables cut corflute cleanly up to 10 mm, with smooth edges and consistent rounded corners, ideal for professional signage and protection panels.

We UV direct print on corflute and then knife-cut to final size and shape. This keeps registration tight, reduces handling and speeds up delivery for large campaigns.

Store layouts, dielines and campaign templates with us for fast reprints — ideal for builders, real estate networks and brands that regularly roll out corflute signage nationally.

Clear specs on sheet sizes, fluting direction, hole placements and finishing options, plus predictable lead times and consistent re-runs for repeat orders.

Production in Botany NSW with national shipping — suited to local projects, multi-site rollouts and ongoing corflute signage programs.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on corflute cutting, UV printing and best practice when designing corflute signage and panels.

Whether you need a handful of construction signs or a full campaign of printed corflute panels, our digital knife and UV printing workflow is set up for trade-ready results and predictable lead times. Upload your files or contact us to plan your next corflute project.

Typical applications include real estate signs, construction site signage, event signage, directional boards, yard signs and temporary retail displays. We work with real estate agents, builders, event companies and retail marketers across all sectors.

For corflute cutting and printing that delivers affordable, lightweight signage ready for quick installation, upload your files or contact us to discuss printing options and quantities.

Corflute Cutting in Sydney. Laser Cutting Experts Offers High-Precision Corflute Cutting Services in Sydney Australia.