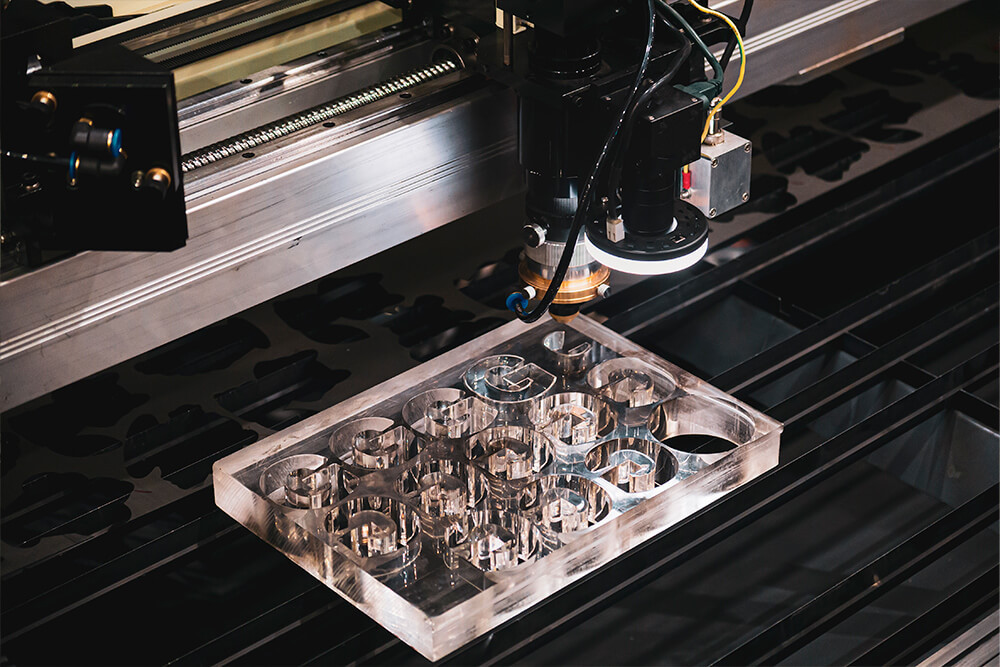

Production-grade CO₂ laser cutting for plastics, timber, foam, rubber and composites — crisp edges, no tooling and fast turnaround. Ideal for acrylic letters, display panels, packaging inserts, architectural elements and custom components. Upload DXF / AI / SVG for instant pricing and Australia-wide delivery.

CO₂ laser cutting is the go-to process for high-precision plastics and internal finishes — perfect for signage, display, architectural, packaging and point-of-sale work.

Internal production limits for flat cutting.

Marine-grade plywood must be CNC-routed, not laser cut.

Max values shown are our in-house limits for reliable production quality.

Up to 1200 × 900 mm. Larger projects can be tiled and joined.

Polished edges on acrylic and crisp details on plastics and timber, straight off the machine.

Ideal for letters, logos, lightbox faces, feature panels and internal architectural finishes.

Update artwork or dimensions without waiting on jigs, dies or CNC tooling.

Low setup overhead and efficient nesting keep total job cost down, even on mixed part runs.

Digital files drive the process — parts match between batches and across rollouts.

We understand deadlines, site dates and rollouts — with clear tolerances and predictable lead times.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for detailed guidance on CO₂ laser cutting of acrylic, plastics, timber and foam, and best practice for flat parts used in signage, displays and packaging.

Our CO₂ laser cutting service in Sydney is built for signmakers, joiners, shopfitters, designers, and manufacturers who need clean acrylic and plastic parts with tight repeatability. By combining smart nesting with dialled-in cut settings for each material, we produce parts that often go straight into assembly, illumination or installation with minimal hand finishing.

Typical applications include acrylic letters and logos, lightbox faces, display panels, POS units, decorative screens, wayfinding signage, packaging inserts, jigs and interior feature elements. We work with everyone from design studios and agencies through to fabricators, printers, and end users who need a production partner.

Whether you need a single prototype display or a full rollout of laser-cut panels, CO₂ laser cutting is usually the most efficient way to produce flat plastic and timber components with premium edge quality. Upload your files through the instant calculator, or contact us if you’d like help optimising your design for CO₂ laser cutting.

CO2 Laser Cutting in Sydney. Laser Cutting Experts Offers High-Precision CO2 Laser Cutting Services in Sydney Australia.