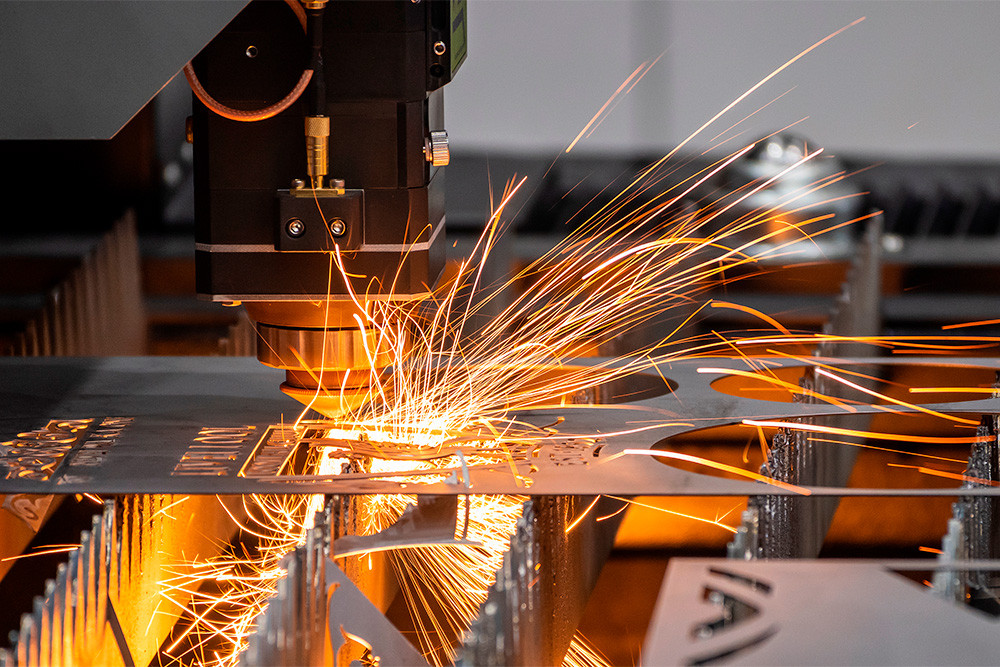

Get production‑grade parts with fiber (fibre) laser cutting metal — clean edges, tight tolerances and quick turnaround. Our metal laser cutting service cuts sheet metal fast. Upload DXF/DWG/SVG for instant pricing and ship Australia‑wide.

Simple reference for quoting and DFM. For thicker gauges or special grades, just ask.

Max values shown are our in-house limits for reliable production quality. If your spec requires thicker gauges or different grades, talk to an expert.

Max thicknesses shown are our in-house limits for reliable production quality.

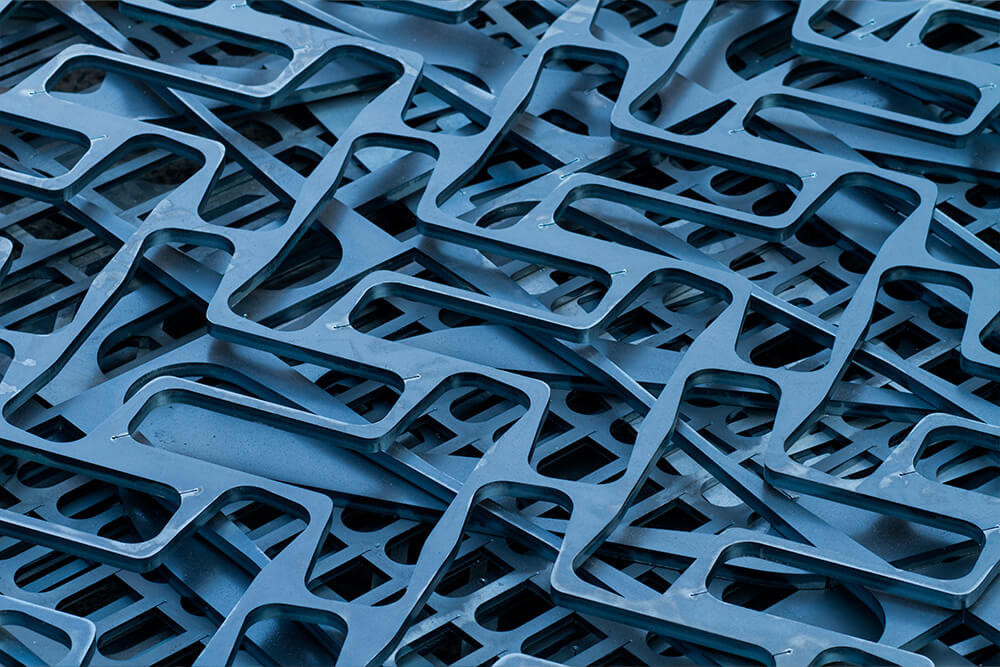

Up to 3000 × 1500 mm (larger on request). Nesting optimised to reduce waste and cost.

High cycle speeds with tight tolerances for better unit pricing on production runs.

Crisp edges with minimal cleanup — ideal for parts that fit and finish cleanly.

Smart nesting and efficient programming reduce waste and total job cost.

Energy‑efficient process and recyclable scrap minimise environmental impact.

From decorative screens to precision brackets — consistent results across part types.

DFM help, clear tolerances and predictable lead times for B2B schedules.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for detailed guidance on fiber laser cutting metal (also fibre laser cutting) and best practice for sheet metal parts.

Fiber Laser Cutting in Sydney. Laser Cutting Experts Offers High-Precision Fiber Laser Cutting Services in Sydney Australia.