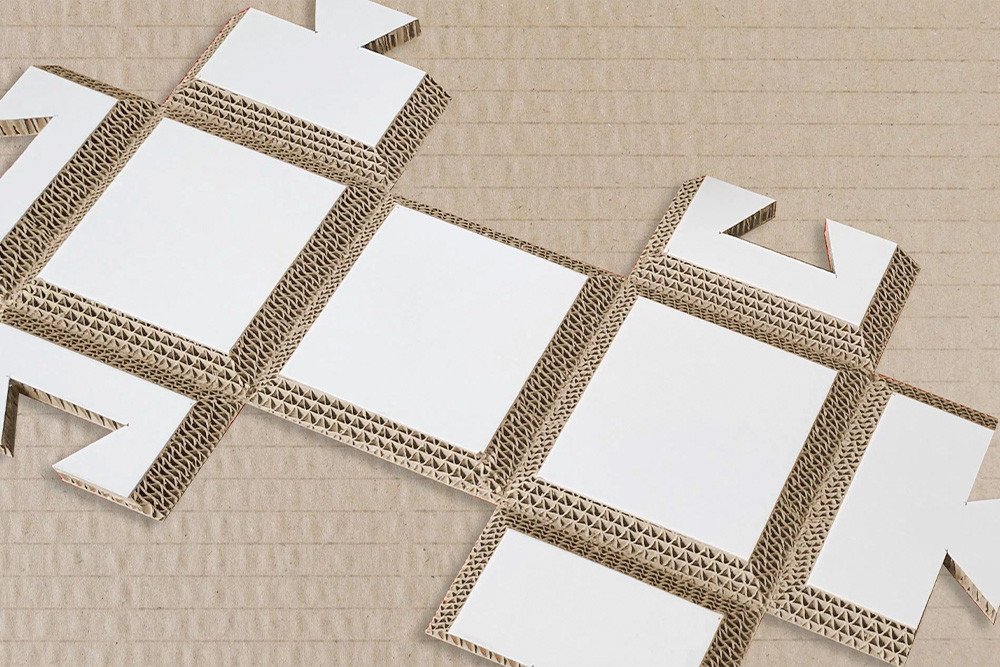

Trade-grade PP honeycomb cutting for lightweight, rigid panels used in signage, displays, construction and industrial applications. We use high-precision CNC router and digital knife cutting to process polypropylene honeycomb panels from one-offs to large production runs. PP honeycomb offers an excellent stiffness-to-weight ratio — ideal where weight, strength and recyclability matter.

We cut polypropylene honeycomb panels for a wide range of industries that need lightweight, rigid and durable sheet materials. Flat parts only — no forming in-house. CNC router and digital knife cutting provide clean edges and accurate profiles, ready to assemble or bond with other components.

PP honeycomb is a lightweight polypropylene core bonded to skins (often polypropylene, aluminium or printed laminates). The table below reflects typical thicknesses we encounter in signage, events and industrial work. Exact availability depends on the panel system, skin type and supplier, and can be confirmed when quoting.

| PP honeycomb thickness | Typical use |

|---|---|

| 5–8 mm PP honeycomb | Lightweight panels for small displays, inserts and packaging elements. |

| 10–12 mm PP honeycomb | Common thickness for signage backers, exhibition panels and POS structures. |

| 15–20 mm PP honeycomb | Heavier-duty wall panels, plinths, fascias and structural display elements. |

| Above 20 mm PP honeycomb | Specialised structural or industrial panels (job-dependent, confirm in advance). |

*Thickness ranges above are indicative for PP honeycomb panels used in signage, events, construction and industrial work. If you are supplying a proprietary panel system, include product data so we can confirm the most suitable cutting method and tooling.

PP honeycomb panels are typically supplied in large-format sheet sizes, ideal for exhibitions and construction. Our cutting beds are sized for full boards, with efficient nesting to minimise waste and keep unit costs down across one-off projects and full campaigns.

We focus on flat PP honeycomb panel cutting. If panels will be edge-capped, bonded to printed skins or assembled into larger structures, we can cut the flat components, mark features and help with packing them logically for install.

We work with lightweight PP honeycomb panels regularly for signage, exhibitions and construction projects. Toolpaths, feeds and nesting are tuned specifically for core panels to avoid tearing and deliver clean, accurate edges.

Once we have your panel sizes, cut-outs and fixing details dialled in, we can support regular rollouts and repeat builds with predictable pricing, timing and packing — ideal for national fitouts and campaign refreshes.

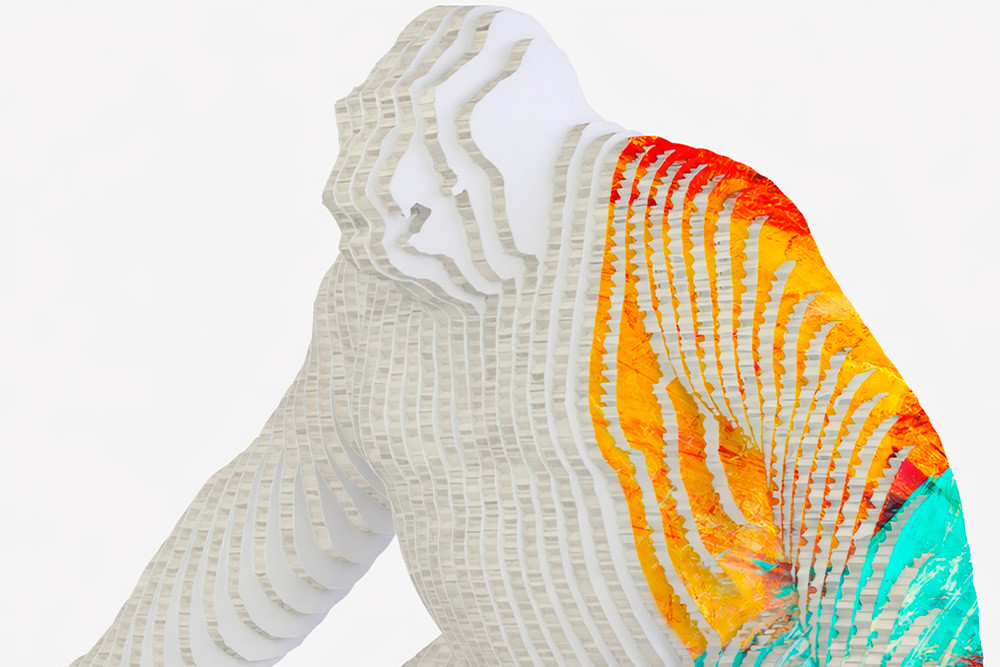

PP honeycomb panels are often combined with printed skins or additional fabrication. We can work from your drawings or artwork and help ensure that cut-outs, fixings and panel sizes align with other trades such as printers, joiners or builders.

Clear specs on panel type, thickness, edge requirements, hole positions and tolerances, plus realistic lead times and consistent re-runs. Our workflow is designed for trade clients, fabricators and agencies who need dependable outcomes on PP honeycomb jobs.

Production in Botany NSW with national shipping — suited to local exhibition builds, multi-site rollouts and ongoing programs using PP honeycomb systems.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on PP honeycomb cutting, design tips and how PP honeycomb compares with other lightweight materials for signage, events and construction.

Whether you need a handful of PP honeycomb display panels or a full national rollout of lightweight wall and ceiling panels, our CNC router and digital knife workflow is set up for trade-ready results and predictable lead times. Upload your files or contact us to plan your next PP honeycomb project.

Typical applications include exhibition displays, event signage, retail displays, ceiling panels, wall cladding and lightweight partitions. We work with exhibition builders, event companies, shopfitters and interior designers across commercial projects.

For PP honeycomb cutting that delivers lightweight, rigid panels ready for exhibition, event or fitout installation, upload your files or contact us to discuss panel specifications and project requirements.

PP Honeycomb Cutting in Sydney. Laser Cutting Experts Offers High-Precision PP Honeycomb Cutting Services in Sydney Australia.