Flat laser cut parts and CNC routered components for engineering workshops, fabricators and OEMs. Mild steel, stainless, aluminium and engineering plastics — ready for welding, bolting and assembly. Upload DXF for instant pricing from our Sydney-based laser cutting team.

We support busy engineering workshops, steel fabricators, OEM manufacturers and maintenance teams with flat laser cut parts that drop straight into welding and assembly. Ideal for production runs, jigs and one-off problem solvers.

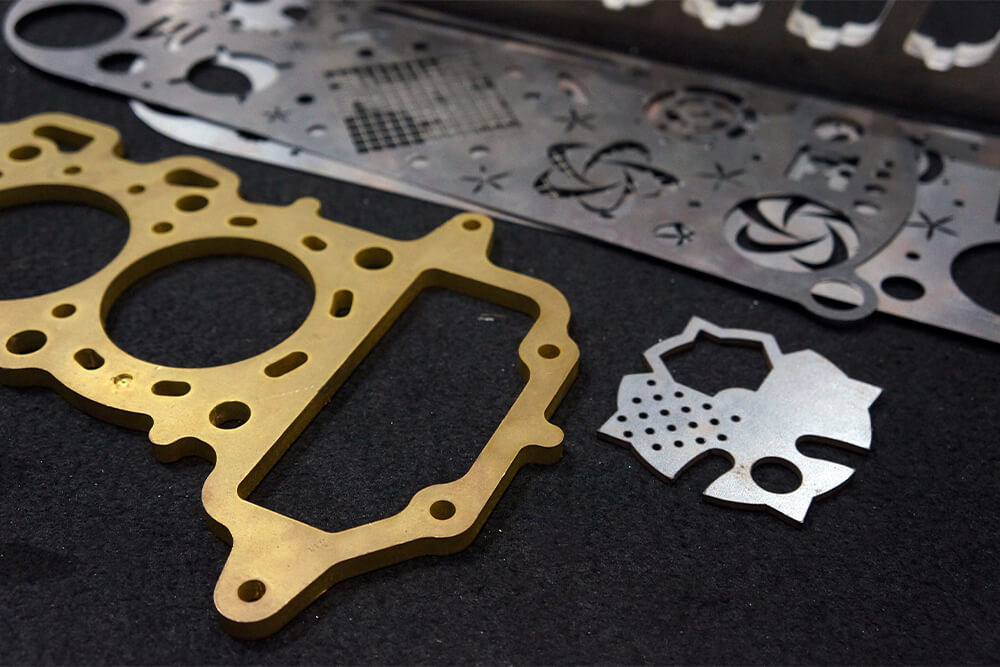

Typical in-house materials we cut for engineering and fabrication projects.

For very thick plate or specialised alloys, talk to us about feasibility before ordering.

Router-cut materials are processed on our CNC router where laser is not suitable.

Values shown are our normal production window for consistent edge quality and reasonable lead times.

Up to 3000 × 1500 mm for metals. Plastics and boards typically up to 2440 × 1220 mm. Larger projects can be tiled, spliced or jointed.

We specialise in flat laser cut parts, not full fabrication. That means quick turnaround on plates, brackets, gussets and shims that you weld, bolt and assemble in-house.

Drawings in, nests prepared, parts cut and clearly labelled. We understand site dates, shutdowns and maintenance windows — and quote realistic lead times up front.

We optimise material usage across plates and jobs wherever practical. Once dialled in, parts can be reordered from the same DXF and nest for consistent fit-up between batches.

Use our stock of common sheet sizes for most engineering steels, or send your own plate where suitable. Either way, you get a single cutting partner that learns your standards.

Based in Botany, we ship across Sydney, Melbourne and Brisbane. Phone, email or visit the workshop to discuss tricky parts before you commit to a full run.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Laser Cutting Experts is set up as a trade partner for engineering and fabrication, not a retail metal shop. Our focus is flat laser cut parts and CNC-routed components that drop into your own fabrication workflow with minimal drama.

Our laser cutting service in Sydney is built for long-term relationships with engineering and fabrication clients. We keep communication tight, explain what is and isn't realistic, and remember your preferences on corner relief, tabbing, marking and labelling. The aim is simple: parts that arrive when you expect them and fit the way you drew them.

Typical jobs range from small bracket packs and gusset kits through to full plate sets for frames, platforms and machinery. We also help with maintenance and breakdown work where a worn or damaged part needs to be replicated quickly from a sketch or sample.

If you have upcoming work in engineering, structural steel, metal fabrication or OEM manufacturing, send through your DXFs or a brief. We can advise on material choice, plate thickness and small drawing tweaks that will help your job run smoother through both our machines and your workshop.

Laser Cutting Engineering & Fabrication in Sydney. Laser Cutting Experts Offers High-Precision Laser Cutting Services for Engineering & Fabrication in Sydney Australia.