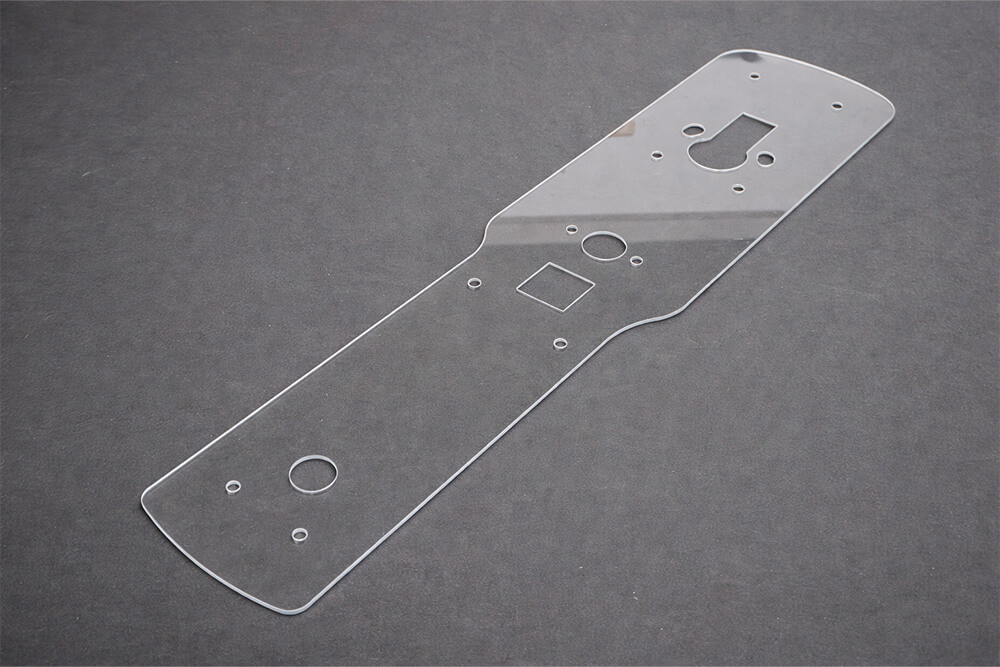

Production-grade PETG sheet cutting for flat panels, safety screens and display work. We process PETG primarily on our CO₂ laser cutters, with CNC routing used where required for thicker sections or specific edge requirements. PETG sits between acrylic and polycarbonate — tougher than acrylic, easier to cut than polycarbonate — and is widely used for guards, glazing and signage.

We cut PETG sheets for safety screens, glazing and display applications across signage, retail and industrial projects. Flat parts only — no thermoforming in-house. Our workflow is set up for repeatable PETG cutting on CO₂ laser and CNC router.

Solid PETG sheets are supplied in similar thicknesses to acrylic and are often used as a tougher alternative where impact resistance and ease of cutting both matter. The table below reflects typical ranges we see in signage and industrial projects. Exact availability depends on brand, grade and supplier.

| PETG type | Typical thickness range | Notes |

|---|---|---|

| Clear PETG sheet | ≈ 2–10 mm | Screens, guards, glazing and covers. |

| Tinted / coloured PETG | ≈ 2–8 mm | Where a tinted or brand colour panel is required. |

| Thin PETG films | ≈ 0.5–2 mm | Overlays, labels, fascia protection and flexible panels. |

*Thickness ranges above are indicative for PETG sheets used in signage, display and industrial work. If your project specifies a particular brand, grade or thickness, include that in your enquiry so we can confirm availability and the most suitable cutting method (laser vs router) before quoting.

We focus on flat PETG cutting. If your job involves forming or bending, we can cut the flat blanks ready for your plastic fabricator.

PETG sheets are typically supplied in standard board sizes used for signage and glazing. Our CO₂ laser and CNC beds are sized for full boards, with nesting to minimise waste and keep unit costs competitive.

Our workflow is tuned for PETG screens, covers and panels — flat parts that arrive drilled, profiled and ready to install in retail, industrial or public environments.

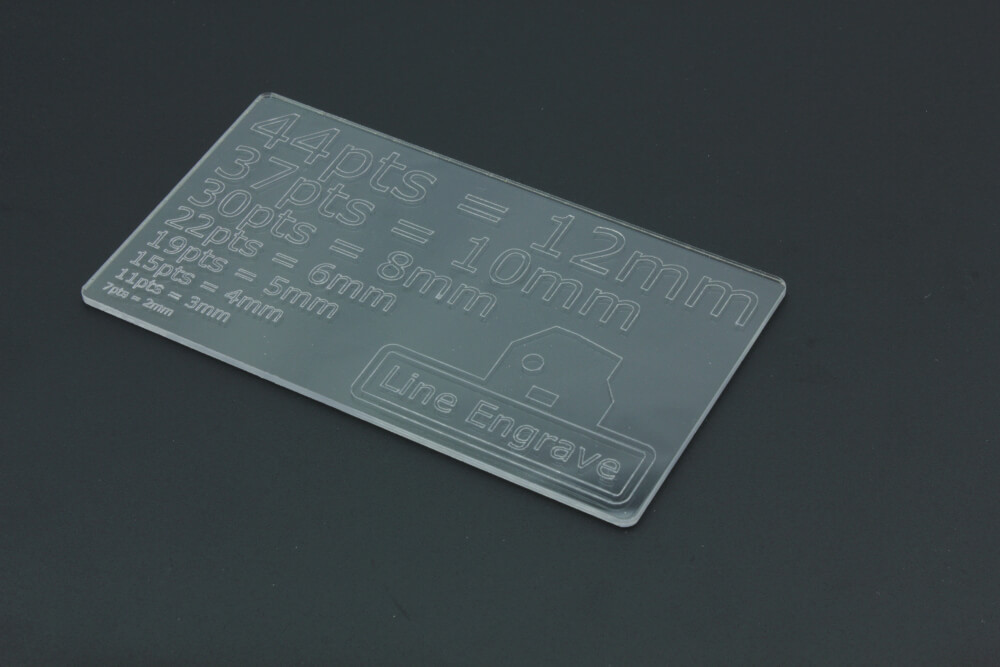

Most PETG cutting is done on CO₂ laser for speed and consistency; CNC routing is brought in where thickness or design demands it. Thin films are handled on the digital knife table.

PETG sits between acrylic and polycarbonate. We can advise when PETG cutting is the best option versus acrylic (better clarity, more brittle) or PC (tougher, harder to laser cut cleanly).

Clear guidance on sheet thickness, fixing details and corner radii, plus predictable lead times and consistent re-runs when you need replacement PETG screens.

Production in Botany NSW with national shipping — suited to ongoing PETG screen programs, fitouts and signage projects.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on PETG cutting, CO₂ laser cutting, CNC routing, digital knife cutting and design tips for PETG parts.

Whether you need PETG counter screens, machine guards or clear panels for a fitout, our CO₂ laser, CNC and knife workflows are set up for repeatable, trade-ready results. Upload your files or contact us to discuss the best way to cut PETG for your project.

Typical applications include sneeze screens, counter barriers, machine guards, protective panels, display cases and retail partitions. We work with shopfitters, office fitout contractors, manufacturers and facilities managers across commercial sectors.

For PETG cutting that balances impact resistance with cost-effectiveness, upload your files or contact us to discuss material specifications and application requirements.

PETG Cutting in Sydney. Laser Cutting Experts Offers High-Precision PETG Cutting Services in Sydney Australia.