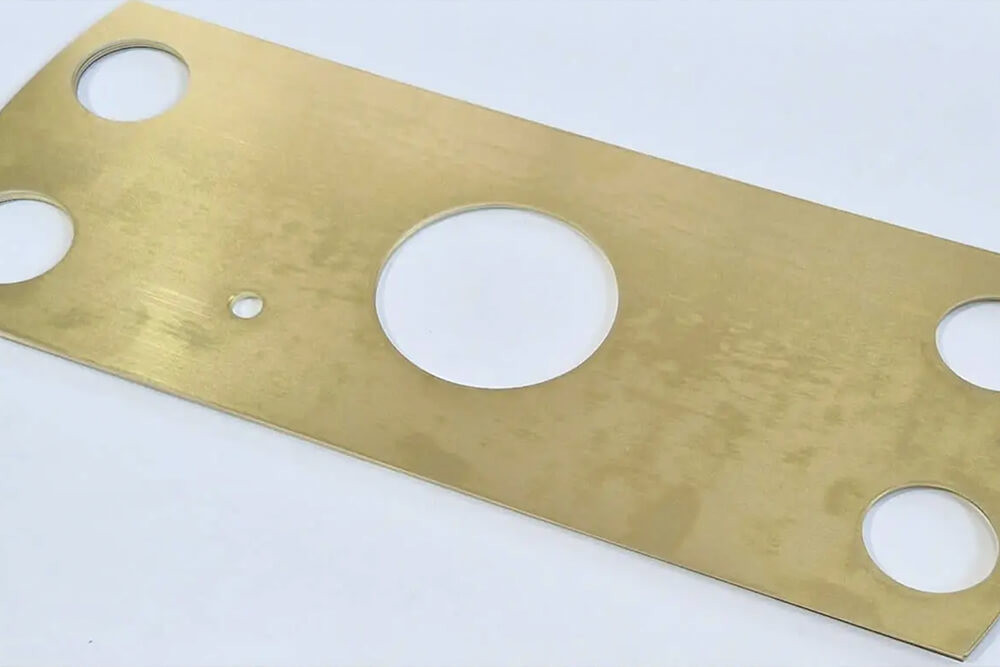

We cut brass sheet from flat panels for components, signage, plaques and decorative work. Fiber laser and CNC cutting for brass sheets up to 3000mm x 1500mm – tuned for clean edges, tight profiles and consistent results across production runs.

Brass is used where appearance, corrosion resistance and machinability all matter. It is a favourite for high-end details, electrical and fluid hardware, and parts that need to look good as well as perform. We mostly cut brass for:

Brass is a copper‑zinc alloy with excellent machinability, a warm metallic appearance and good corrosion resistance in many environments. It is more reflective and thermally conductive than mild steel or stainless, so we tune laser parameters for clean edges and minimal heat marking, and use CNC routing where appropriate.

For brass we generally cut with fiber laser using appropriate assist gas, switching to CNC where edge or fixture requirements demand it.

We can work from DXF, DWG, STEP (with 2D extracts), AI or PDF files, or reverse-engineer from existing brass parts where needed.

Our goal is to deliver brass parts that can move straight into finishing, assembly or install with minimal re-work.

Brass is usually on show. Our flat-part workflow is tuned for visible metals – from nesting and edge quality through to how parts are handled, labelled and packed for finishing and install.

We understand how brass integrates with timber, stone, glass and painted finishes. Clearances, hole sizes and edge details are planned so parts sit flush and align across various substrates.

Brass plates and trims often sit beside laser-cut steel, aluminium, acrylic and timber. Because we cut those materials as well, we can help align patterns, fixing centres and tolerances across the whole kit.

We regularly work behind the scenes for metal shops, joiners, sign companies, architects and designers. Consistent quality, predictable lead times and stable references are the focus.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Brass Cutting in Sydney. Laser Cutting Experts Offers High-Precision Brass Cutting Services in Sydney Australia.