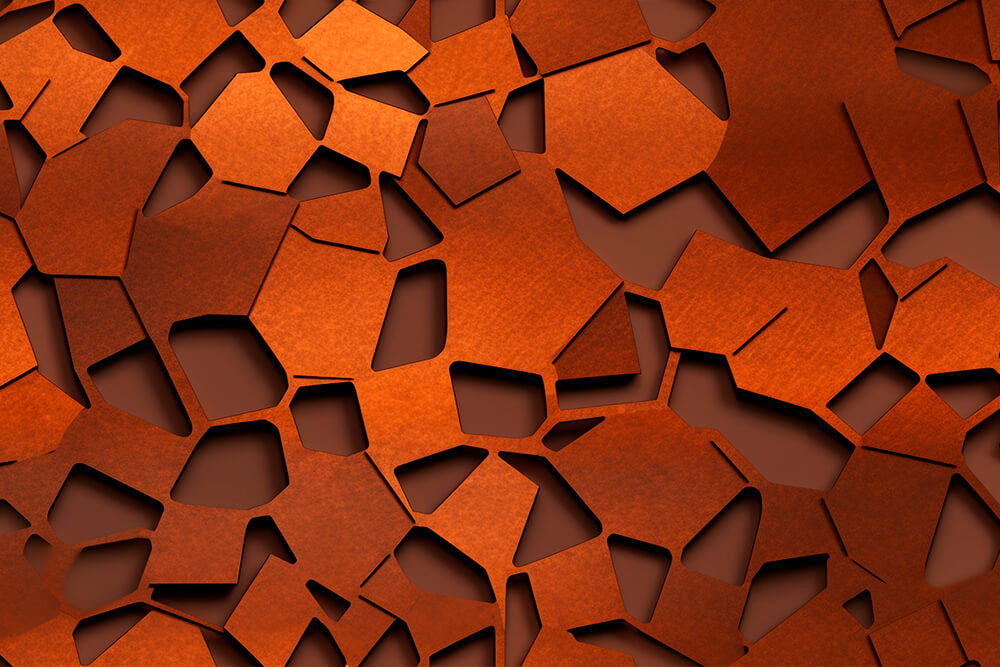

Trade-grade Corten steel cutting for architecture, landscaping, signage and fabrication. We use high-precision fiber laser cutting to process weathering steel sheets into screens, panels, brackets and feature elements. Flat parts only — supplied cut, cleaned and ready for welding, framing or direct installation.

We cut Corten (weathering) steel panels for clients who need accurate, repeatable flat parts ready for fabrication or installation. Flat components only — no folding, rolling or forming in-house. Fiber laser cutting delivers clean edges and detailed patterns while preserving the character of the steel.

We cut Corten (weathering) steel panels for clients who need accurate, repeatable flat parts ready for fabrication or installation. Flat components only — no folding, rolling or forming in-house. Fiber laser cutting delivers clean edges and detailed patterns while preserving the character of the steel.

We focus on flat Corten steel cutting. Folding, welding, framing and on-site installation are normally handled by your fabrication or building teams. We can align hole patterns, slots and panel sizes to suit your downstream processes.

Our fiber laser beds are set up for Corten steel sheets up to 3000 × 1500 mm, covering common panel sizes used in Australian architecture and fabrication. Smart nesting reduces waste and helps keep unit costs competitive for both smaller projects and large feature walls.

We regularly cut Corten panels for architects, builders, landscapers and sign companies. Patterns, fixing details and panel layouts are planned with real site conditions and fixing methods in mind.

Once screen patterns and panel sizes are proven, we can repeat them easily — ideal for townhouses, multi-level buildings, estates and standard product ranges in Corten steel.

Work from DXF/DWG, AI, PDFs or sketches. We can assist with trimming patterns to panel edges, adding fixing holes and planning joints so seams fall in logical, buildable locations.

Clear specs on grade, thickness, panel size and fixings, plus realistic lead times and predictable re-runs. We are geared to support fabricators, builders, landscapers and sign shops that work with Corten regularly.

Get instant prices for laser-cut and CNC-cut parts across metals, plastics, composites and more — available 24/7.

Launch the calculator to upload DXF, DWG or vector files and see live pricing for flat laser-cut parts. Pricing updates instantly based on material, thickness and cut time.

Open instant calculatorAccepted formats: DXF / DWG / AI / SVG / PDF (vector).

Send measurements, sketches or existing parts and we’ll create cut-ready drawings, then quote via the same engine.

Simple plates and brackets can often be drawn and quoted the same day.

Open the items below for more detail on designing with Corten steel and how to get the best out of laser cut weathering steel panels.

Whether you need a one-off feature panel, a full set of screens for a development, or Corten signage and trims as part of a larger package, our fiber laser workflow is set up for trade-ready results and predictable lead times. Upload your files or contact us to plan your next Corten steel cutting project.

Typical applications include architectural screens, feature walls, garden edging, decorative facades, landscape elements, signage panels and fire pits. We work with architects, landscape designers, builders and metal fabricators across residential and commercial projects.

For Corten steel cutting that delivers distinctive weathering steel elements with precise patterns, upload your files or contact us to discuss panel sizing, weathering considerations and installation requirements.

Corten Steel Cutting in Sydney. Laser Cutting Experts Offers High-Precision Corten Steel Cutting Services in Sydney Australia.